CONSTRUCTION AND USE OF DRAWING- INSTRUMENTS.

15

by the square, after which the end of a paper-folder, or

other smooth article, is rubbed along the “lap,” to press out

the superfluous glue. The same operation being rapidly

applied in succession to the other edges, the sheet is left

to dry, and ultimately, by the contraction, turns out per-

fectly flat and tense. When paste or melted glue is not

to be had conveniently, a cake of glue may be dipped in

water and rubbed on the margins of the board at the

proper places.

With panelled boards, as described, the panel is taken

out, and the frame inverted; the paper being first damped

on the back with a sponge, slightly charged with water,

is applied equally over the opening to leave equal mar-

gins, and is pressed and secured into its seat by the panel

and bars. This is a ready enough way of laying a sheet,

and for damp sheets is more expeditious than the gluing

system. But for general use, plain boards are sufficient.

T Square.

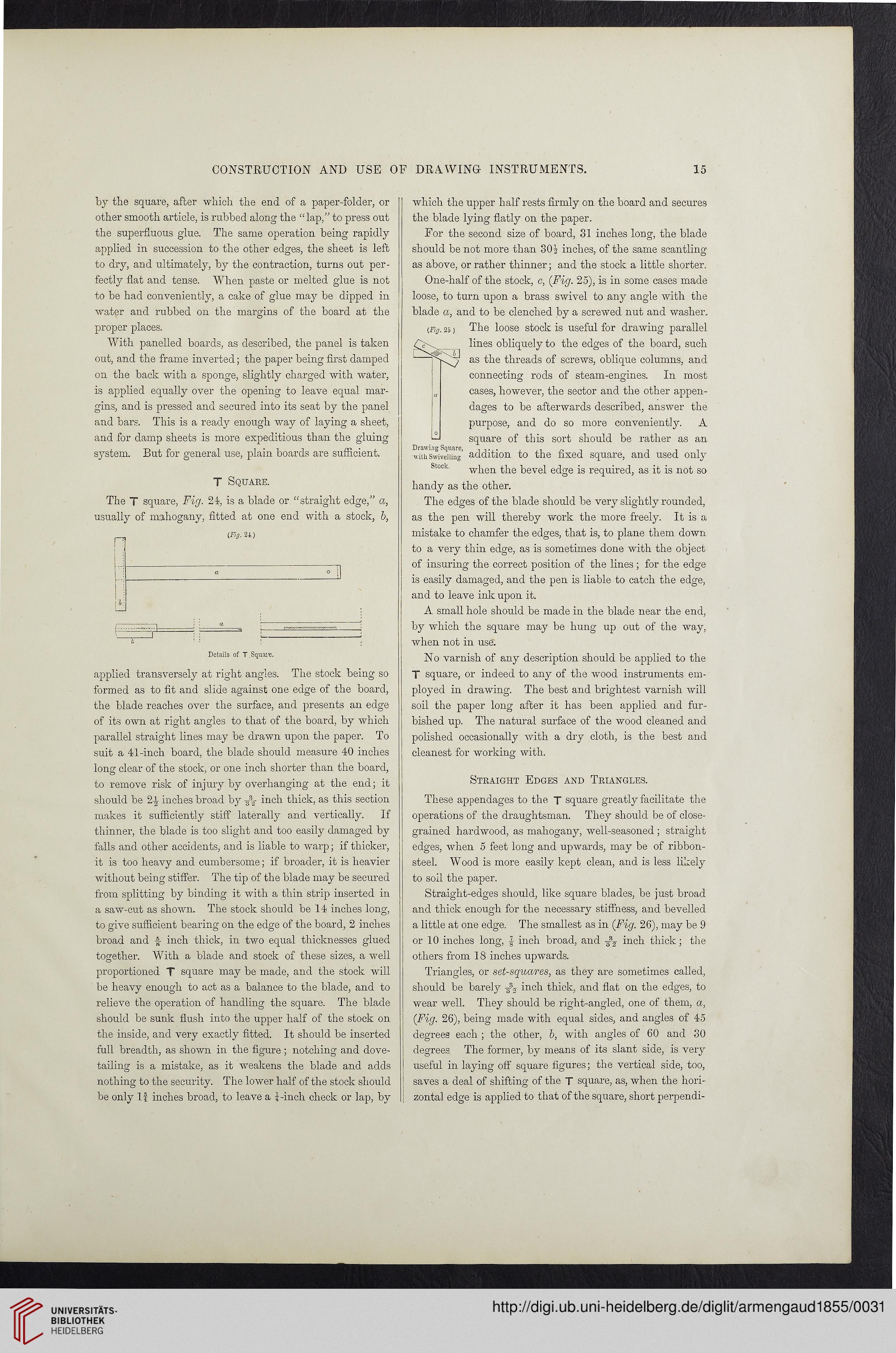

The T square, Fig. 2d, is a blade or “straight edge,” a,

usually of mahogany, fitted at one end with a stock, b,

p, &9- 34.)

I i

H-n

! n o :

! 5

Details of T.Squase.

applied transversely at right angles. The stock being so

formed as to fit and slide against one edge of the board,

the blade reaches over the surface, and presents an edge

of its own at right angles to that of the board, by which

parallel straight lines may be drawn upon the paper. To

suit a 41-inch board, the blade should measure 40 inches

long clear of the stock, or one inch shorter than the board,

to remove risk of injury by overhanging at the end; it

should be inches broad by inch thick, as this section

makes it sufficiently stiff laterally and vertically. If

thinner, the blade is too slight and too easily damaged by

falls and other accidents, and is liable to warp; if thicker,

it is too heavy and cumbersome; if broader, it is heavier

without being stiffen The tip of the blade may be secured

from splitting by binding it with a thin strip inserted in

a saw-cut as shown. The stock should be 14 inches long,

to give sufficient bearing on the edge of the board, 2 inches

broad and •§- inch thick, in two equal thicknesses glued

together. With a blade and stock of these sizes, a well

proportioned T square may be made, and the stock will

be heavy enough to act as a balance to the blade, and to

relieve the operation of handling the square. The blade

should be sunk flush into the upper half of the stock on

the inside, and very exactly fitted. It should be inserted

full breadth, as shown in the figure ; notching and dove-

tailing is a mistake, as it weakens the blade and adds

nothing to the security. The lower half of the stock should

be only If inches broad, to leave a 1-inch check or lap, by

which the upper half rests firmly on the board and secures

the blade lying flatly on the paper.

For the second size of board, 81 inches long, the blade

should be not more than 301 inches, of the same scantling

as above, or rather thinner; and the stock a little shorter.

One-half of the stock, c, (Fig. 25), is in some cases made

loose, to turn upon a brass swivel to any angle with the

blade a, and to be clenched by a screwed nut and washer,

(Fir/. 25) The loose stock is useful for drawing parallel

lines obliquely to the edges of the board, such

as the threads of screws, oblique columns, and

connecting rods of steam-engines. In most

cases, however, the sector and the other appen-

dages to be afterwards described, answer the

purpose, and do so more conveniently. A

square of this sort should be rather as an

with Swivelling' addition to the fixed square, and used only

Stock when the bevel edge is required, as it is not so

handy as the other.

The edges of the blade should be very slightly rounded,

as the pen will thereby work the more freely. It is a

mistake to chamfer the edges, that is, to plane them down

to a very thin edge, as is sometimes done with the object

of insuring the correct position of the lines; for the edge

is easily damaged, and the pen is liable to catch the edge,

and to leave ink upon it.

A small hole should be made in the blade near the end,

by which the square may be hung up out of the way,

when not in use.

No varnish of any description should be applied to the

T square, or indeed to any of the wood instruments em-

ployed in drawing. The best and brightest varnish will

soil the paper long after it has been applied and fur-

bished up. The natural surface of the wood cleaned and

polished occasionally with a dry cloth, is the best and

cleanest for working with.

Straight Edges and Triangles.

These appendages to the T square greatly facilitate the

operations of the draughtsman. They should be of close-

grained hardwood, as mahogany, well-seasoned ; straight

edges, when 5 feet long and upwards, may be of ribbon-

steel. Wood is more easily kept clean, and is less likely

to soil the paper.

Straight-edges should, like square blades, be just broad

and thick enough for the necessary stiffness, and bevelled

a little at one edge. The smallest as in (Fig. 26), may be 9

or 10 inches long, f inch broad, and inch thick; the

others from 18 inches upwards.

Triangles, or set-squares, as they are sometimes called,

should be barely inch thick, and flat on the edges, to

wear well. They should be right-angled, one of them, a,

(Fig. 26), being made with equal sides, and angles of 45

degrees each ; the other, b, with angles of 60 and 30

degrees The former, by means of its slant side, is very

l useful in laying off square figures; the vertical side, too,

saves a deal of shifting of the T square, as, when the hori-

; zontal edge is applied to that of the square, short perpendi-

15

by the square, after which the end of a paper-folder, or

other smooth article, is rubbed along the “lap,” to press out

the superfluous glue. The same operation being rapidly

applied in succession to the other edges, the sheet is left

to dry, and ultimately, by the contraction, turns out per-

fectly flat and tense. When paste or melted glue is not

to be had conveniently, a cake of glue may be dipped in

water and rubbed on the margins of the board at the

proper places.

With panelled boards, as described, the panel is taken

out, and the frame inverted; the paper being first damped

on the back with a sponge, slightly charged with water,

is applied equally over the opening to leave equal mar-

gins, and is pressed and secured into its seat by the panel

and bars. This is a ready enough way of laying a sheet,

and for damp sheets is more expeditious than the gluing

system. But for general use, plain boards are sufficient.

T Square.

The T square, Fig. 2d, is a blade or “straight edge,” a,

usually of mahogany, fitted at one end with a stock, b,

p, &9- 34.)

I i

H-n

! n o :

! 5

Details of T.Squase.

applied transversely at right angles. The stock being so

formed as to fit and slide against one edge of the board,

the blade reaches over the surface, and presents an edge

of its own at right angles to that of the board, by which

parallel straight lines may be drawn upon the paper. To

suit a 41-inch board, the blade should measure 40 inches

long clear of the stock, or one inch shorter than the board,

to remove risk of injury by overhanging at the end; it

should be inches broad by inch thick, as this section

makes it sufficiently stiff laterally and vertically. If

thinner, the blade is too slight and too easily damaged by

falls and other accidents, and is liable to warp; if thicker,

it is too heavy and cumbersome; if broader, it is heavier

without being stiffen The tip of the blade may be secured

from splitting by binding it with a thin strip inserted in

a saw-cut as shown. The stock should be 14 inches long,

to give sufficient bearing on the edge of the board, 2 inches

broad and •§- inch thick, in two equal thicknesses glued

together. With a blade and stock of these sizes, a well

proportioned T square may be made, and the stock will

be heavy enough to act as a balance to the blade, and to

relieve the operation of handling the square. The blade

should be sunk flush into the upper half of the stock on

the inside, and very exactly fitted. It should be inserted

full breadth, as shown in the figure ; notching and dove-

tailing is a mistake, as it weakens the blade and adds

nothing to the security. The lower half of the stock should

be only If inches broad, to leave a 1-inch check or lap, by

which the upper half rests firmly on the board and secures

the blade lying flatly on the paper.

For the second size of board, 81 inches long, the blade

should be not more than 301 inches, of the same scantling

as above, or rather thinner; and the stock a little shorter.

One-half of the stock, c, (Fig. 25), is in some cases made

loose, to turn upon a brass swivel to any angle with the

blade a, and to be clenched by a screwed nut and washer,

(Fir/. 25) The loose stock is useful for drawing parallel

lines obliquely to the edges of the board, such

as the threads of screws, oblique columns, and

connecting rods of steam-engines. In most

cases, however, the sector and the other appen-

dages to be afterwards described, answer the

purpose, and do so more conveniently. A

square of this sort should be rather as an

with Swivelling' addition to the fixed square, and used only

Stock when the bevel edge is required, as it is not so

handy as the other.

The edges of the blade should be very slightly rounded,

as the pen will thereby work the more freely. It is a

mistake to chamfer the edges, that is, to plane them down

to a very thin edge, as is sometimes done with the object

of insuring the correct position of the lines; for the edge

is easily damaged, and the pen is liable to catch the edge,

and to leave ink upon it.

A small hole should be made in the blade near the end,

by which the square may be hung up out of the way,

when not in use.

No varnish of any description should be applied to the

T square, or indeed to any of the wood instruments em-

ployed in drawing. The best and brightest varnish will

soil the paper long after it has been applied and fur-

bished up. The natural surface of the wood cleaned and

polished occasionally with a dry cloth, is the best and

cleanest for working with.

Straight Edges and Triangles.

These appendages to the T square greatly facilitate the

operations of the draughtsman. They should be of close-

grained hardwood, as mahogany, well-seasoned ; straight

edges, when 5 feet long and upwards, may be of ribbon-

steel. Wood is more easily kept clean, and is less likely

to soil the paper.

Straight-edges should, like square blades, be just broad

and thick enough for the necessary stiffness, and bevelled

a little at one edge. The smallest as in (Fig. 26), may be 9

or 10 inches long, f inch broad, and inch thick; the

others from 18 inches upwards.

Triangles, or set-squares, as they are sometimes called,

should be barely inch thick, and flat on the edges, to

wear well. They should be right-angled, one of them, a,

(Fig. 26), being made with equal sides, and angles of 45

degrees each ; the other, b, with angles of 60 and 30

degrees The former, by means of its slant side, is very

l useful in laying off square figures; the vertical side, too,

saves a deal of shifting of the T square, as, when the hori-

; zontal edge is applied to that of the square, short perpendi-