Stencil Craft

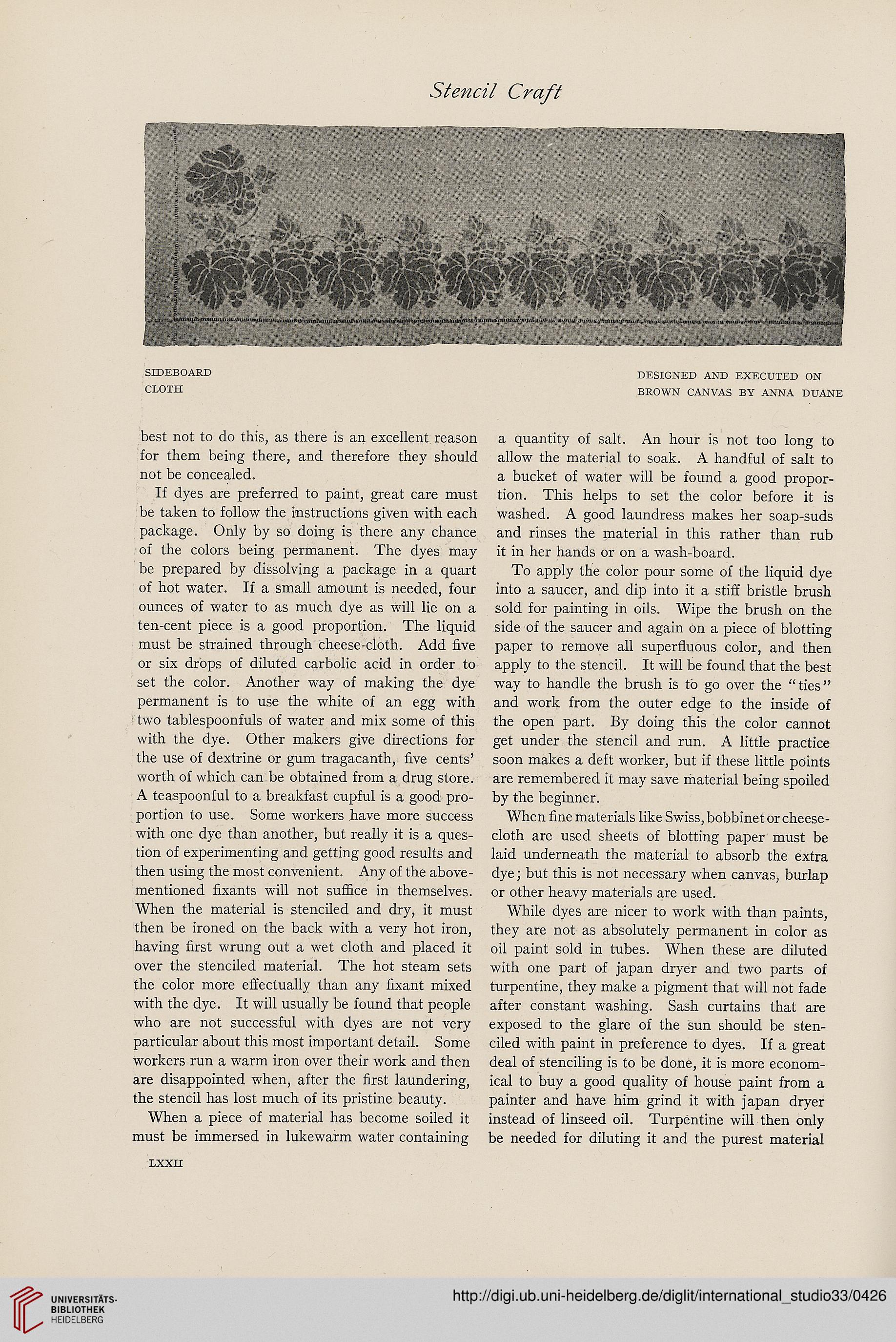

SIDEBOARD DESIGNED AND EXECUTED ON

CLOTH BROWN CANVAS BY ANNA DUANE

best not to do this, as there is an excellent reason

for them being there, and therefore they should

not be concealed.

If dyes are preferred to paint, great care must

be taken to follow the instructions given with each

package. Only by so doing is there any chance

of the colors being permanent. The dyes may

be prepared by dissolving a package in a quart

of hot water. If a small amount is needed, four

ounces of water to as much dye as will lie on a

ten-cent piece is a good proportion. The liquid

must be strained through cheese-cloth. Add five

or six drops of diluted carbolic acid in order to

set the color. Another way of making the dye

permanent is to use the white of an egg with

two tablespoonfuls of water and mix some of this

with the dye. Other makers give directions for

the use of dextrine or gum tragacanth, five cents’

worth of which can be obtained from a drug store.

A teaspoonful to a breakfast cupful is a good pro-

portion to use. Some workers have more success

with one dye than another, but really it is a ques-

tion of experimenting and getting good results and

then using the most convenient. Any of the above-

mentioned fixants will not suffice in themselves.

When the material is stenciled and dry, it must

then be ironed on the back with a very hot iron,

having first wrung out a wet cloth and placed it

over the stenciled material. The hot steam sets

the color more effectually than any fixant mixed

with the dye. It will usually be found that people

who are not successful with dyes are not very

particular about this most important detail. Some

workers run a warm iron over their work and then

are disappointed when, after the first laundering,

the stencil has lost much of its pristine beauty.

When a piece of material has become soiled it

must be immersed in lukewarm water containing

a quantity of salt. An hour is not too long to

allow the material to soak. A handful of salt to

a bucket of water will be found a good propor-

tion. This helps to set the color before it is

washed. A good laundress makes her soap-suds

and rinses the material in this rather than rub

it in her hands or on a wash-board.

To apply the color pour some of the liquid dye

into a saucer, and dip into it a stiff bristle brush

sold for painting in oils. Wipe the brush on the

side of the saucer and again on a piece of blotting

paper to remove all superfluous color, and then

apply to the stencil. It will be found that the best

way to handle the brush is to go over the “ties”

and work from the outer edge to the inside of

the open part. By doing this the color cannot

get under the stencil and run. A little practice

soon makes a deft worker, but if these little points

are remembered it may save material being spoiled

by the beginner.

When fine materials like Swiss, bobbinet or cheese-

cloth are used sheets of blotting paper must be

laid underneath the material to absorb the extra

dye; but this is not necessary when canvas, burlap

or other heavy materials are used.

While dyes are nicer to work with than paints,

they are not as absolutely permanent in color as

oil paint sold in tubes. When these are diluted

with one part of japan dryer and two parts of

turpentine, they make a pigment that will not fade

after constant washing. Sash curtains that are

exposed to the glare of the sun should be sten-

ciled with paint in preference to dyes. If a great

deal of stenciling is to be done, it is more econom-

ical to buy a good quality of house paint from a

painter and have him grind it with japan dryer

instead of linseed oil. Turpentine will then only

be needed for diluting it and the purest material

LXXII

SIDEBOARD DESIGNED AND EXECUTED ON

CLOTH BROWN CANVAS BY ANNA DUANE

best not to do this, as there is an excellent reason

for them being there, and therefore they should

not be concealed.

If dyes are preferred to paint, great care must

be taken to follow the instructions given with each

package. Only by so doing is there any chance

of the colors being permanent. The dyes may

be prepared by dissolving a package in a quart

of hot water. If a small amount is needed, four

ounces of water to as much dye as will lie on a

ten-cent piece is a good proportion. The liquid

must be strained through cheese-cloth. Add five

or six drops of diluted carbolic acid in order to

set the color. Another way of making the dye

permanent is to use the white of an egg with

two tablespoonfuls of water and mix some of this

with the dye. Other makers give directions for

the use of dextrine or gum tragacanth, five cents’

worth of which can be obtained from a drug store.

A teaspoonful to a breakfast cupful is a good pro-

portion to use. Some workers have more success

with one dye than another, but really it is a ques-

tion of experimenting and getting good results and

then using the most convenient. Any of the above-

mentioned fixants will not suffice in themselves.

When the material is stenciled and dry, it must

then be ironed on the back with a very hot iron,

having first wrung out a wet cloth and placed it

over the stenciled material. The hot steam sets

the color more effectually than any fixant mixed

with the dye. It will usually be found that people

who are not successful with dyes are not very

particular about this most important detail. Some

workers run a warm iron over their work and then

are disappointed when, after the first laundering,

the stencil has lost much of its pristine beauty.

When a piece of material has become soiled it

must be immersed in lukewarm water containing

a quantity of salt. An hour is not too long to

allow the material to soak. A handful of salt to

a bucket of water will be found a good propor-

tion. This helps to set the color before it is

washed. A good laundress makes her soap-suds

and rinses the material in this rather than rub

it in her hands or on a wash-board.

To apply the color pour some of the liquid dye

into a saucer, and dip into it a stiff bristle brush

sold for painting in oils. Wipe the brush on the

side of the saucer and again on a piece of blotting

paper to remove all superfluous color, and then

apply to the stencil. It will be found that the best

way to handle the brush is to go over the “ties”

and work from the outer edge to the inside of

the open part. By doing this the color cannot

get under the stencil and run. A little practice

soon makes a deft worker, but if these little points

are remembered it may save material being spoiled

by the beginner.

When fine materials like Swiss, bobbinet or cheese-

cloth are used sheets of blotting paper must be

laid underneath the material to absorb the extra

dye; but this is not necessary when canvas, burlap

or other heavy materials are used.

While dyes are nicer to work with than paints,

they are not as absolutely permanent in color as

oil paint sold in tubes. When these are diluted

with one part of japan dryer and two parts of

turpentine, they make a pigment that will not fade

after constant washing. Sash curtains that are

exposed to the glare of the sun should be sten-

ciled with paint in preference to dyes. If a great

deal of stenciling is to be done, it is more econom-

ical to buy a good quality of house paint from a

painter and have him grind it with japan dryer

instead of linseed oil. Turpentine will then only

be needed for diluting it and the purest material

LXXII