^ ^<9^ <977 /'777t?77<9^

building high up from the street tha.t every singie

piece of this band shali be exact in shape or coior,

but in interior decoration and detail work which is

examined closely, unless the color is absolutely

harmonious and unless each piece matches the

other exactly in shape, the effect will be spoiled. It

does not pay the companies which are turning out

material on a tonnage basis and doing large work

to change their methods in order to hre some small

piece to a stronger color value. The faience com-

panies are endeavoring to do just this work. Where

a panel or border is wanted of exceptionally strong

color or a great variety of color, the faience manu-

facturer is equipped and can afford to devote the

time and trouble necessary to get the proper artistic

result. For this reason it seems to me that rather

than conflict, the terra cotta companies and the

faience companies can be of a material benefit to

one another by working harmoniously.

A piece of faience should have the earmark of

the personality of the craftsman upon it. Any

article which is turned out in large quantities must

necessarily lose something of the originality and the

personality of the artist. Therefore, let us keep in

mind that by glazed terra cotta we understand a

glazed material for the exterior or interior decora-

tion of a building, which will be technically made

as weli, but which will not give the depth or variety

of color, or the individual characteristics of the

artist, to the extent that can be produced in a piece

of faience.

About twelve years ago faience was hrst pro-

duced in this country, and the three companies

interested in its manufacture have had considerable

trouble impressing the architects and public with

this difference. It is very gratifying at the present

time that there is a much better understandingof the

material and a very much keener interest than

formerly. If one suggested, a fewyears ago,putting

strong color on our buildings, he was laughed at

and told that color in Italy or the southern coun-

tries was well enough, but that America, for climatic

and temperamental reasons, could not appreciate

color on its buildings. This is a fallacy. There is

no reason why color cannot be employed to beautify

the exterior of buildings here as well as in Italy.

It is only a question of using that color correctly.

When we see such buildings as the new Brooklyn

Academyof Music, and others, werealize that there

is beginning to be felt a desire for more color in the

decoration of our buildings.

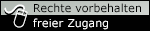

A held which opens up the greatest possibilities

for the use of colored faience is for the decoration of

concrete and stucco buildings. The chief objec-

tion to a concrete house is the monotony of its ap-

pearance. When a few bits of color are added its

monotony is broken, and by the use of panels,

friezes, bands and other architectural members in

strong color, concrete buildings can be made ex-

tremely beautiful, for the dull gray of the con-

crete is a perfect background for the color of the

faience. This fact was appreciated by the Della

Robbias in Italy, where you find their faience on

so many stucco buildings. The only thing neces-

sary for a satisfactory result is that not too much

color be used, but just enough to give the touch of

color which will break the monotony and make

a harmonious result.

Faience is manufactured by mixing hre clays

together with water into a plastic state. The

material is then formed into the desired shapes.

It is then allowed to dry in dryers and is placed in a

kiln or oven and hred to an ex-

tremely high heat. At this stage

of the process it is a hard buS-

colored material and ready to be

glazed. The glazes are made

by chemicals which in heating

melt and form a material of a

glassy nature. These glazes are

applied in the liquid state, the

material being either dipped in

them or the glaze painted or

sprayed on. When dry it forms

a coating of about one-eighth of

an inch inthickness, and the piece

is then ready to be put into the

kiln a second time for the gloss

burning; from this second burn-

ing this giaze comes out practi-

SUBWAY STATION

PANEL AND FRIEZE

DESIGNED BY

HEINS AND LAFARGE

XX

building high up from the street tha.t every singie

piece of this band shali be exact in shape or coior,

but in interior decoration and detail work which is

examined closely, unless the color is absolutely

harmonious and unless each piece matches the

other exactly in shape, the effect will be spoiled. It

does not pay the companies which are turning out

material on a tonnage basis and doing large work

to change their methods in order to hre some small

piece to a stronger color value. The faience com-

panies are endeavoring to do just this work. Where

a panel or border is wanted of exceptionally strong

color or a great variety of color, the faience manu-

facturer is equipped and can afford to devote the

time and trouble necessary to get the proper artistic

result. For this reason it seems to me that rather

than conflict, the terra cotta companies and the

faience companies can be of a material benefit to

one another by working harmoniously.

A piece of faience should have the earmark of

the personality of the craftsman upon it. Any

article which is turned out in large quantities must

necessarily lose something of the originality and the

personality of the artist. Therefore, let us keep in

mind that by glazed terra cotta we understand a

glazed material for the exterior or interior decora-

tion of a building, which will be technically made

as weli, but which will not give the depth or variety

of color, or the individual characteristics of the

artist, to the extent that can be produced in a piece

of faience.

About twelve years ago faience was hrst pro-

duced in this country, and the three companies

interested in its manufacture have had considerable

trouble impressing the architects and public with

this difference. It is very gratifying at the present

time that there is a much better understandingof the

material and a very much keener interest than

formerly. If one suggested, a fewyears ago,putting

strong color on our buildings, he was laughed at

and told that color in Italy or the southern coun-

tries was well enough, but that America, for climatic

and temperamental reasons, could not appreciate

color on its buildings. This is a fallacy. There is

no reason why color cannot be employed to beautify

the exterior of buildings here as well as in Italy.

It is only a question of using that color correctly.

When we see such buildings as the new Brooklyn

Academyof Music, and others, werealize that there

is beginning to be felt a desire for more color in the

decoration of our buildings.

A held which opens up the greatest possibilities

for the use of colored faience is for the decoration of

concrete and stucco buildings. The chief objec-

tion to a concrete house is the monotony of its ap-

pearance. When a few bits of color are added its

monotony is broken, and by the use of panels,

friezes, bands and other architectural members in

strong color, concrete buildings can be made ex-

tremely beautiful, for the dull gray of the con-

crete is a perfect background for the color of the

faience. This fact was appreciated by the Della

Robbias in Italy, where you find their faience on

so many stucco buildings. The only thing neces-

sary for a satisfactory result is that not too much

color be used, but just enough to give the touch of

color which will break the monotony and make

a harmonious result.

Faience is manufactured by mixing hre clays

together with water into a plastic state. The

material is then formed into the desired shapes.

It is then allowed to dry in dryers and is placed in a

kiln or oven and hred to an ex-

tremely high heat. At this stage

of the process it is a hard buS-

colored material and ready to be

glazed. The glazes are made

by chemicals which in heating

melt and form a material of a

glassy nature. These glazes are

applied in the liquid state, the

material being either dipped in

them or the glaze painted or

sprayed on. When dry it forms

a coating of about one-eighth of

an inch inthickness, and the piece

is then ready to be put into the

kiln a second time for the gloss

burning; from this second burn-

ing this giaze comes out practi-

SUBWAY STATION

PANEL AND FRIEZE

DESIGNED BY

HEINS AND LAFARGE

XX