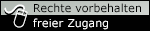

BRASS CANDLE

SHADES

DESIGNED AND EXECUTED BY

MRS. FRED. WURZBURG AND MRS. BERTHA BLISS

GRAND RAPIDS SCHOOL OF APPLIED ARTS

c

UT BRASS WORK

BY MABEL TUKE PRIESTMAN

TnERE are few things more inter-

esting to work in than thin sheet metai,

although there is a general impression that it is a

somewhat difhcult art. Sheet brass is so soft and

pliable that it easily iends itself to cutting, and many

beautiful and original designs can be made in the

following manner:

Lamp and candle shades give opportunity for

this decorative form of brass work, and it is not

a dilhcult problem to design and execute a metal

shade in harmony with some odd-shaped jar or

vase which we may already possess.

Very few tools are required for making pierced

or cut brass. A block of hardwood and a block

of softwood sold for ordinary repousse work can

be utilized, or even a portion of a plank can be

fastened to the table. A vise and wooden mallet,

a steel hammer and a set of nails will be required

for the shaping of the articles, while the cutting

out is done by means of a fret or scroll saw. If

the brass is very thin, it can be cut by means of

scissors, which is somewhat easier than a fret saw

for the beginner. A file will be required for

smoothing the edges, and a riveting set must also

be procured.

A beginner usually chooses a lamp or candle

shade, as they are particularly easy to construct.

To make a reading lamp it is necessary to get a

satisfactory base, and the shade must be designed

in perfect harmony with it. In making the shade

for the reading lamp, the first step is to make a

paper pattern of the shadeandexperimentwith the

different sizes and flares, so as to decide the right

proportion and flare of the shade to the lamp itself.

A shade may be made with the following meas-

urements for each side : 16 inches for the lower hori-

zontal edge, 4 inches for the top horizontal edge

and 10 inches for the depth of the shade. Before

rnaking the design, it is best to have an accurate

pattern of each side cut from stiff bristol board.

The design may then be drawn for one side of the

shade. Then make a design on drawing papcr

for one of these panels. Then draw an inner line

all round the inside and half an inch frorn the outer

edge, leaving a central space for the cut design.

The outer margin of half an inch serves as a frame

to which the design is joined with pathways of

metal, giving somewhat the effect of a stencil. In

planning a design of this kind, a great deal of at-

tention must be given to getting well-proportioned

background spaces, and all sharp points and angles

must be eliminated.

The design having been carefully planned, pro-

ceed to draw a definite outline around each open-

ing to be cut out. India ink is the best medium

for drawing these lines. The first design must

always be kept for future work, and now trace as

many panels as the lamp requires from the orig-

inal drawing. This is best done on Japanese rice

paper. The design now being complete on the

paper, we are ready for the metal. Copper or

brass may be used in any thickness in gauge be-

tween numbers 20 and 24.

For a lamp shade of copper, Nurnber 24 is

perhaps the best to work with, as it is light

in weight and yet stiff enough to hold its shape.

Lay the accurate pattern of the panel upon the

metal and mark around it with a nail. Then

cut out the hve sides, following the scratched line

with the rnetal shears. With hour paste fasten to

each panel an India-ink tracing of the design,

and when these are perfectly dry they are ready

for the sawing. Now proceed to bore one or rnore

holes through every opening with a hand drill,

placing them near but not on the line. Then pro-

ceed to cut the rnetal with the fret saw. These

usuallv measure six and seven inches in depth. An

xcix