DRAWING OF MACHINERY.

G3

vent the segmental edges sliding upon each other during

the operation, they are sometimes rubbed with chalk or

ilour-rosin.

The curvilinear faces of the tooth being thus defined,

the portion dd of the pitch circle is traced upon the

plane C C, and the segment B is removed; the board

C C is then fixed upon a slip of deal E, somewhat greater

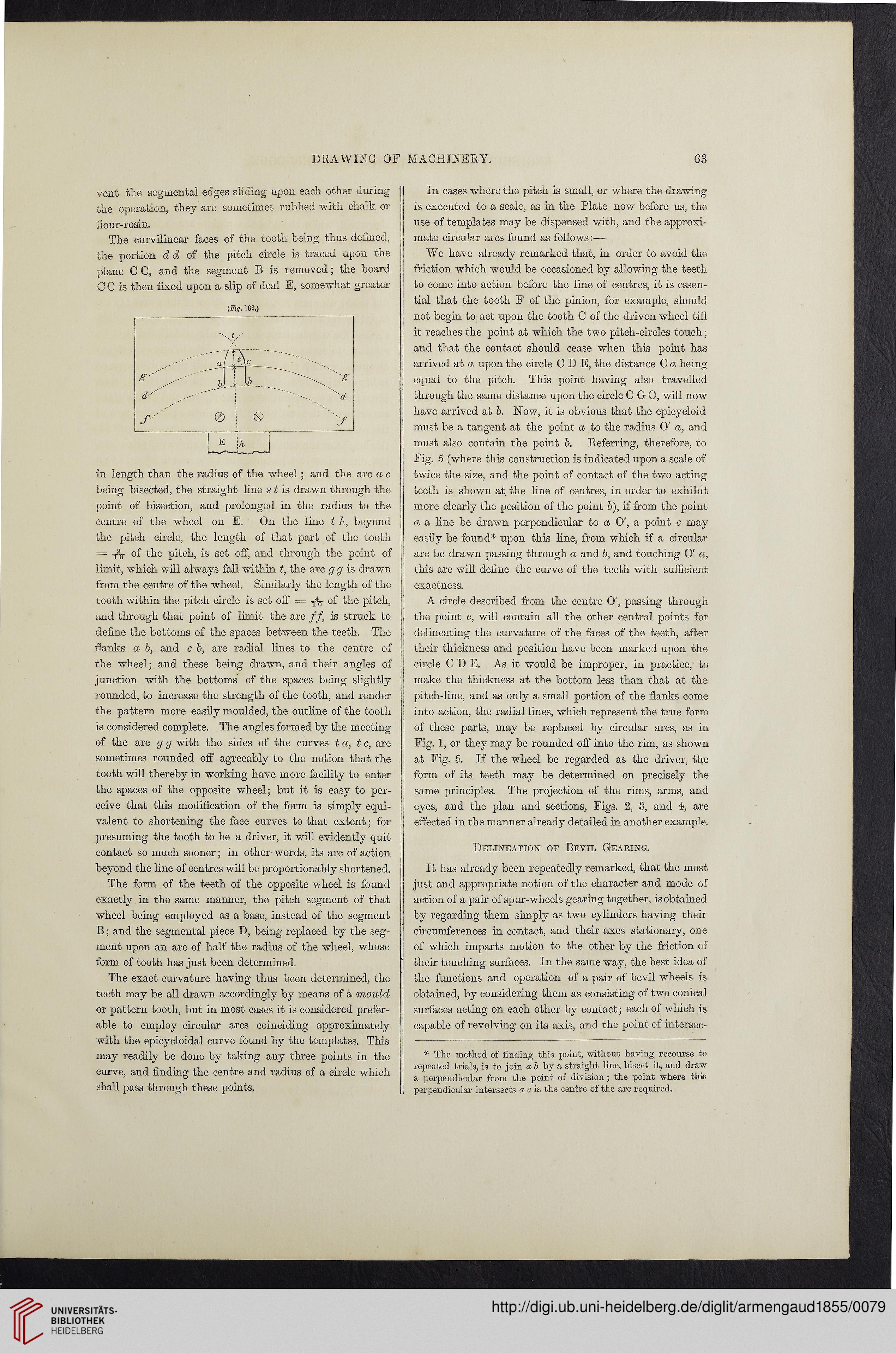

(Fig. 182.)

in length than the radius of the wheel; and the arc a c

being bisected, the straight line s t is drawn through the

point of bisection, and prolonged in the radius to the

centre of the wheel on E. On the line t h, beyond

the pitch circle, the length of that part of the tooth

= Yq- of the pitch, is set off, and through the point of

limit, which will always fall within t, the arc g g is drawn

from the centre of the wheel. Similarly the length of the

tooth within the pitch circle is set off = W of the pitch,

and through that point of limit the arc //, is struck to

define the bottoms of the spaces between the teeth. The

flanks a b, and c b, are radial lines to the centre of

the wheel; and these being drawn, and their angles of

junction with the bottoms of the spaces being slightly

rounded, to increase the strength of the tooth, and render

the pattern more easily moulded, the outline of the tooth

is considered complete. The angles formed by the meeting

of the arc g g with the sides of the curves t a, t c, are

sometimes rounded off agreeably to the notion that the

tooth will thereby in working have more facility to enter

the spaces of the opposite wheel; but it is easy to per-

ceive that this modification of the form is simply equi-

valent to shortening the face curves to that extent; for

presuming the tooth to be a driver, it will evidently quit

contact so much sooner; in other words, its arc of action

beyond the line of centres will be proportionably shortened.

The form of the teeth of the opposite wheel is found

exactly in the same manner, the pitch segment of that

wheel being employed as a base, instead of the segment

B; and the segmental piece D, being replaced by the seg-

ment upon an arc of half the radius of the wheel, whose

form of tooth has just been determined.

The exact curvature having thus been determined, the

teeth may be all drawn accordingly by means of a mould

or pattern tooth, but in most cases it is considered prefer-

able to employ circular arcs coinciding approximately

with the epicycloidal curve found by the templates. This

may readily be done by taking any three points in the

curve, and finding the centre and radius of a circle which

shall pass through these points.

In cases where the pitch is small, or where the drawing

is executed to a scale, as in the Plate now before us, the

use of templates may be dispensed with, and the approxi-

mate circular arcs found as follows:—

We have already remarked that, in order to avoid the

friction which would be occasioned by allowing the teeth

to come into action before the line of centres, it is essen-

tial that the tooth E of the pinion, for example, should

not begin to act upon the tooth C of the driven wheel till

it reaches the point at which the two pitch-circles touch;

and that the contact should cease when this point has

arrived at a upon the circle C D E, the distance C a being

equal to the pitch. This point having also travelled

through the same distance upon the circle C G 0, will now

have arrived at b. Now, it is obvious that the epicycloid

must be a tangent at the point a to the radius 0' a, and

must also contain the point b. Referring, therefore, to

Fig. 5 (where this construction is indicated upon a scale of

twice the size, and the point of contact of the two acting

teeth is shown at the line of centres, in order to exhibit

more clearly the position of the point 6), if from the point

a a line be drawn perpendicular to a O', a point c may

easily be found* upon this line, from which if a circular

arc be drawn passing through a and b, and touching O' a,

this arc will define the curve of the teeth with sufficient

exactness.

A circle described from the centre O', passing through

the point c, will contain all the other central points for

delineating the curvature of the faces of the teeth, after

their thickness and position have been marked upon the

circle C D E. As it would be improper, in practice, to

make the thickness at the bottom less than that at the

pitch-line, and as only a small portion of the flanks come

into action, the radial lines, which represent the true form

of these parts, may be replaced by circular arcs, as in

Fig. 1, or they may be rounded off into the rim, as shown

at Fig. 5. If the wheel be regarded as the driver, the

form of its teeth may be determined on precisely the

same principles. The projection of the rims, arms, and

eyes, and the plan and sections, Figs. 2, 3, and 4, are

effected in the manner already detailed in another example.

Delineation of Bevil Gearing.

It has already been repeatedly remarked, that the most

just and appropriate notion of the character and mode of

action of a pair of sp ur-wheels gearing together, is obtained

by regarding them simply as two cylinders having their

circumferences in contact, and their axes stationary, one

of which imparts motion to the other by the friction of

their touching surfaces. In the same way, the best idea of

the functions and operation of a pair of bevil wheels is

obtained, by considering them as consisting of two conical

surfaces acting on each other by contact; each of which is

capable of revolving on its axis, and the point of intersec-

* The method of finding this point, without having recourse to

repeated trials, is to join a & by a straight line, bisect it, and draw

a perpendicular from the point of division ; the point where thie

perpendicular intersects a c is the centre of the arc required.

G3

vent the segmental edges sliding upon each other during

the operation, they are sometimes rubbed with chalk or

ilour-rosin.

The curvilinear faces of the tooth being thus defined,

the portion dd of the pitch circle is traced upon the

plane C C, and the segment B is removed; the board

C C is then fixed upon a slip of deal E, somewhat greater

(Fig. 182.)

in length than the radius of the wheel; and the arc a c

being bisected, the straight line s t is drawn through the

point of bisection, and prolonged in the radius to the

centre of the wheel on E. On the line t h, beyond

the pitch circle, the length of that part of the tooth

= Yq- of the pitch, is set off, and through the point of

limit, which will always fall within t, the arc g g is drawn

from the centre of the wheel. Similarly the length of the

tooth within the pitch circle is set off = W of the pitch,

and through that point of limit the arc //, is struck to

define the bottoms of the spaces between the teeth. The

flanks a b, and c b, are radial lines to the centre of

the wheel; and these being drawn, and their angles of

junction with the bottoms of the spaces being slightly

rounded, to increase the strength of the tooth, and render

the pattern more easily moulded, the outline of the tooth

is considered complete. The angles formed by the meeting

of the arc g g with the sides of the curves t a, t c, are

sometimes rounded off agreeably to the notion that the

tooth will thereby in working have more facility to enter

the spaces of the opposite wheel; but it is easy to per-

ceive that this modification of the form is simply equi-

valent to shortening the face curves to that extent; for

presuming the tooth to be a driver, it will evidently quit

contact so much sooner; in other words, its arc of action

beyond the line of centres will be proportionably shortened.

The form of the teeth of the opposite wheel is found

exactly in the same manner, the pitch segment of that

wheel being employed as a base, instead of the segment

B; and the segmental piece D, being replaced by the seg-

ment upon an arc of half the radius of the wheel, whose

form of tooth has just been determined.

The exact curvature having thus been determined, the

teeth may be all drawn accordingly by means of a mould

or pattern tooth, but in most cases it is considered prefer-

able to employ circular arcs coinciding approximately

with the epicycloidal curve found by the templates. This

may readily be done by taking any three points in the

curve, and finding the centre and radius of a circle which

shall pass through these points.

In cases where the pitch is small, or where the drawing

is executed to a scale, as in the Plate now before us, the

use of templates may be dispensed with, and the approxi-

mate circular arcs found as follows:—

We have already remarked that, in order to avoid the

friction which would be occasioned by allowing the teeth

to come into action before the line of centres, it is essen-

tial that the tooth E of the pinion, for example, should

not begin to act upon the tooth C of the driven wheel till

it reaches the point at which the two pitch-circles touch;

and that the contact should cease when this point has

arrived at a upon the circle C D E, the distance C a being

equal to the pitch. This point having also travelled

through the same distance upon the circle C G 0, will now

have arrived at b. Now, it is obvious that the epicycloid

must be a tangent at the point a to the radius 0' a, and

must also contain the point b. Referring, therefore, to

Fig. 5 (where this construction is indicated upon a scale of

twice the size, and the point of contact of the two acting

teeth is shown at the line of centres, in order to exhibit

more clearly the position of the point 6), if from the point

a a line be drawn perpendicular to a O', a point c may

easily be found* upon this line, from which if a circular

arc be drawn passing through a and b, and touching O' a,

this arc will define the curve of the teeth with sufficient

exactness.

A circle described from the centre O', passing through

the point c, will contain all the other central points for

delineating the curvature of the faces of the teeth, after

their thickness and position have been marked upon the

circle C D E. As it would be improper, in practice, to

make the thickness at the bottom less than that at the

pitch-line, and as only a small portion of the flanks come

into action, the radial lines, which represent the true form

of these parts, may be replaced by circular arcs, as in

Fig. 1, or they may be rounded off into the rim, as shown

at Fig. 5. If the wheel be regarded as the driver, the

form of its teeth may be determined on precisely the

same principles. The projection of the rims, arms, and

eyes, and the plan and sections, Figs. 2, 3, and 4, are

effected in the manner already detailed in another example.

Delineation of Bevil Gearing.

It has already been repeatedly remarked, that the most

just and appropriate notion of the character and mode of

action of a pair of sp ur-wheels gearing together, is obtained

by regarding them simply as two cylinders having their

circumferences in contact, and their axes stationary, one

of which imparts motion to the other by the friction of

their touching surfaces. In the same way, the best idea of

the functions and operation of a pair of bevil wheels is

obtained, by considering them as consisting of two conical

surfaces acting on each other by contact; each of which is

capable of revolving on its axis, and the point of intersec-

* The method of finding this point, without having recourse to

repeated trials, is to join a & by a straight line, bisect it, and draw

a perpendicular from the point of division ; the point where thie

perpendicular intersects a c is the centre of the arc required.