?

s7

NEW PRODUCTS AND PROCESSES

Weavers’ Delight

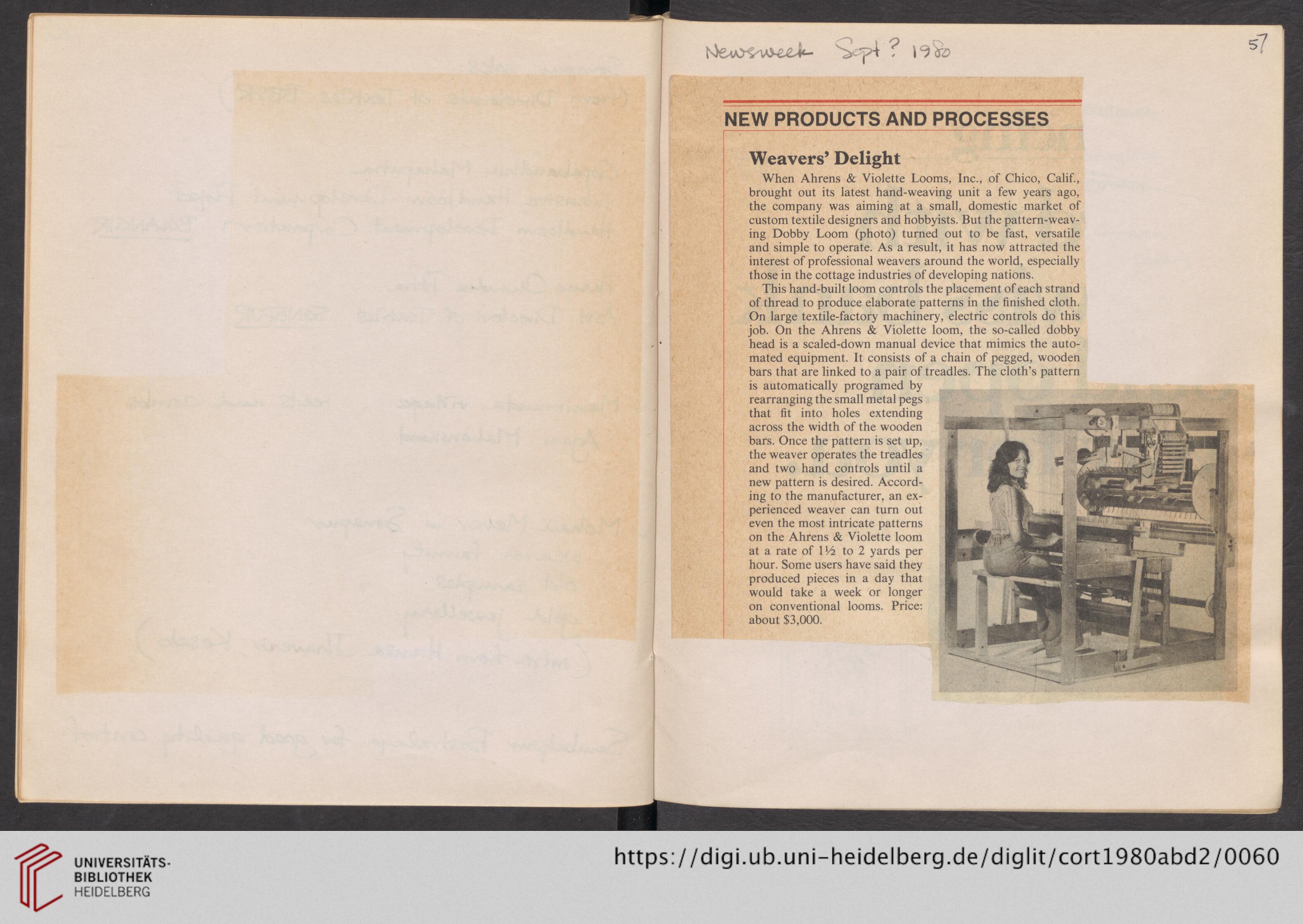

When Ahrens & Violette Looms, Inc., of Chico, Calif.,

brought out its latest hand-weaving unit a few years ago,

the company was aiming at a small, domestic market of

custom textile designers and hobbyists. But the pattern-weav-

ing Dobby Loom (photo) turned out to be fast, versatile

and simple to operate. As a result, it has now attracted the

interest of professional weavers around the world, especially

those in the cottage industries of developing nations.

This hand-built loom controls the placement of each strand

of thread to produce elaborate patterns in the finished cloth.

On large textile-factory machinery, electric controls do this

job. On the Ahrens & Violette loom, the so-called dobby

head is a scaled-down manual device that mimics the auto-

mated equipment. It consists of a chain of pegged, wooden

bars that are linked to a pair of treadles. The cloth’s pattern

is automatically programed by

rearranging the small metal pegs

that fit into holes extending

across the width of the wooden

bars. Once the pattern is set up,

the weaver operates the treadles

and two hand controls until a

new pattern is desired. Accord-

ing to the manufacturer, an ex-

perienced weaver can turn out

even the most intricate patterns

on the Ahrens & Violette loom

at a rate of 114 to 2 yards per

hour. Some users have said they

produced pieces in a day that

would take a week or longer

on conventional looms. Price:

about $3,000.

s7

NEW PRODUCTS AND PROCESSES

Weavers’ Delight

When Ahrens & Violette Looms, Inc., of Chico, Calif.,

brought out its latest hand-weaving unit a few years ago,

the company was aiming at a small, domestic market of

custom textile designers and hobbyists. But the pattern-weav-

ing Dobby Loom (photo) turned out to be fast, versatile

and simple to operate. As a result, it has now attracted the

interest of professional weavers around the world, especially

those in the cottage industries of developing nations.

This hand-built loom controls the placement of each strand

of thread to produce elaborate patterns in the finished cloth.

On large textile-factory machinery, electric controls do this

job. On the Ahrens & Violette loom, the so-called dobby

head is a scaled-down manual device that mimics the auto-

mated equipment. It consists of a chain of pegged, wooden

bars that are linked to a pair of treadles. The cloth’s pattern

is automatically programed by

rearranging the small metal pegs

that fit into holes extending

across the width of the wooden

bars. Once the pattern is set up,

the weaver operates the treadles

and two hand controls until a

new pattern is desired. Accord-

ing to the manufacturer, an ex-

perienced weaver can turn out

even the most intricate patterns

on the Ahrens & Violette loom

at a rate of 114 to 2 yards per

hour. Some users have said they

produced pieces in a day that

would take a week or longer

on conventional looms. Price:

about $3,000.