Enamelling

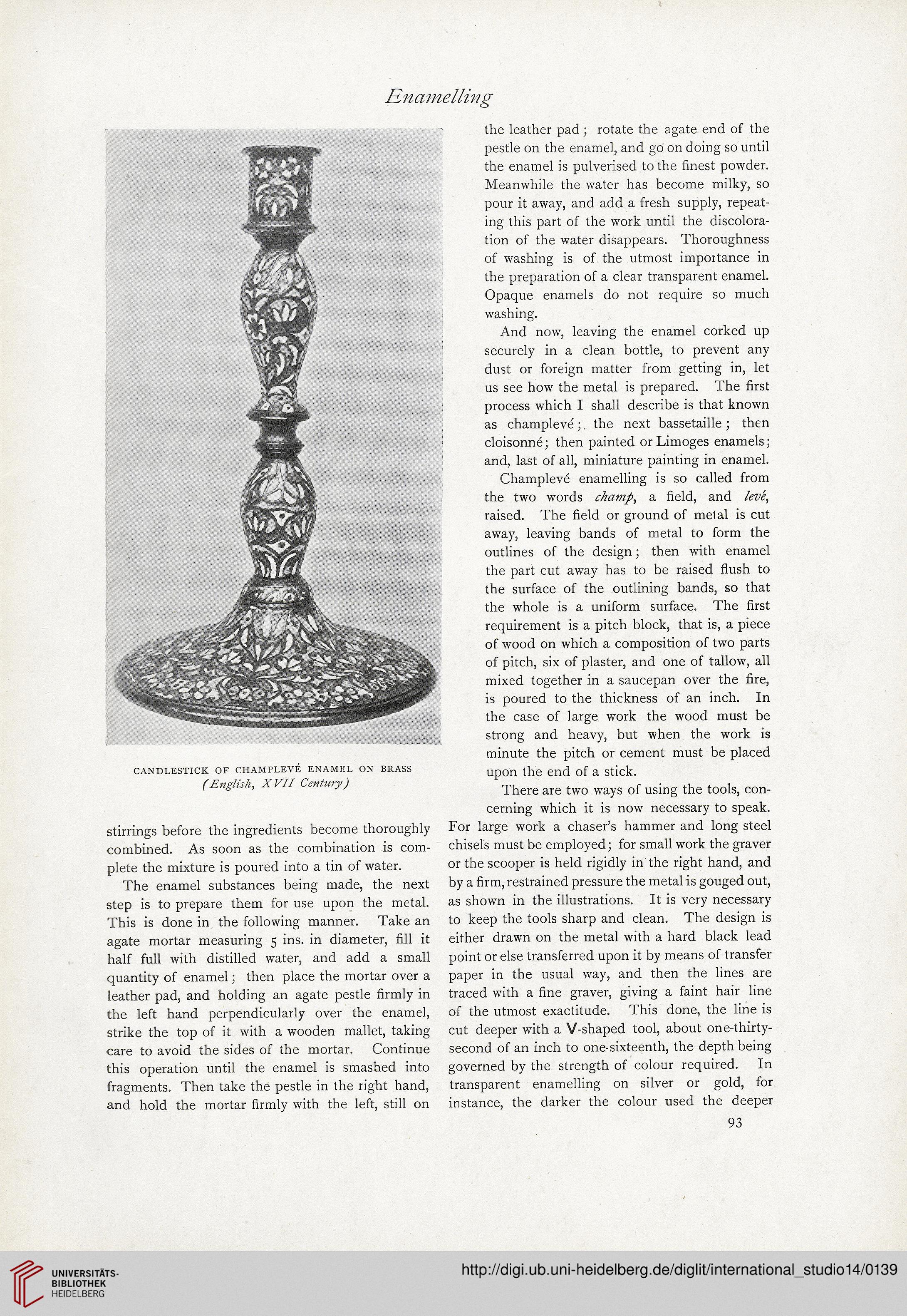

CANDLESTICK OF CHAMPLEVE ENAMEL ON BRASS

(English, X VII Century)

stirrings before the ingredients become thoroughly

combined. As soon as the combination is com-

plete the mixture is poured into a tin of water.

The enamel substances being made, the next

step is to prepare them for use upon the metal.

This is done in the following manner. Take an

agate mortar measuring 5 ins. in diameter, fill it

half full with distilled water, and add a small

quantity of enamel; then place the mortar over a

leather pad, and holding an agate pestle firmly in

the left hand perpendicularly over the enamel,

strike the top of it with a wooden mallet, taking

care to avoid the sides of the mortar. Continue

this operation until the enamel is smashed into

fragments. Then take the pestle in the right hand,

and hold the mortar firmly with the left, still on

' the leather pad ; rotate the agate end of the

pestle on the enamel, and go on doing so until

the enamel is pulverised to the finest powder.

Meanwhile the water has become milky, so

pour it away, and add a fresh supply, repeat-

ing this part of the work until the discolora-

tion of the water disappears. Thoroughness

of washing is of the utmost importance in

the preparation of a clear transparent enamel.

Opaque enamels do not require so much

washing.

And now, leaving the enamel corked up

securely in a clean bottle, to prevent any

dust or foreign matter from getting in, let

us see how the metal is prepared. The first

process which I shall describe is that known

as champleve;, the next bassetaille; then

cloisonnd; then painted or Limoges enamels;

and, last of all, miniature painting in enamel.

Champleve enamelling is so called from

the two words champ, a field, and leve,

raised. The field or ground of metal is cut

away, leaving bands of metal to form the

outlines of the design; then with enamel

the part cut away has to be raised flush to

the surface of the outlining bands, so that

the whole is a uniform surface. The first

requirement is a pitch block, that is, a piece

of wood on which a composition of two parts

of pitch, six of plaster, and one of tallow, all

mixed together in a saucepan over the fire,

is poured to the thickness of an inch. In

the case of large work the wood must be

strong and heavy, but when the work is

minute the pitch or cement must be placed

upon the end of a stick.

There are two ways of using the tools, con-

cerning which it is now necessary to speak.

For large work a chaser’s hammer and long steel

chisels must be employed; for small work the graver

or the scooper is held rigidly in the right hand, and

by a firm, restrained pressure the metal is gouged out,

as shown in the illustrations. It is very necessary

to keep the tools sharp and clean. The design is

either drawn on the metal with a hard black lead

point or else transferred upon it by means of transfer

paper in the usual way, and then the lines are

traced with a fine graver, giving a faint hair line

of the utmost exactitude. This done, the line is

cut deeper with a V-shaped tool, about one-thirty-

second of an inch to one-sixteenth, the depth being

governed by the strength of colour required. In

transparent enamelling on silver or gold, for

instance, the darker the colour used the deeper

93

CANDLESTICK OF CHAMPLEVE ENAMEL ON BRASS

(English, X VII Century)

stirrings before the ingredients become thoroughly

combined. As soon as the combination is com-

plete the mixture is poured into a tin of water.

The enamel substances being made, the next

step is to prepare them for use upon the metal.

This is done in the following manner. Take an

agate mortar measuring 5 ins. in diameter, fill it

half full with distilled water, and add a small

quantity of enamel; then place the mortar over a

leather pad, and holding an agate pestle firmly in

the left hand perpendicularly over the enamel,

strike the top of it with a wooden mallet, taking

care to avoid the sides of the mortar. Continue

this operation until the enamel is smashed into

fragments. Then take the pestle in the right hand,

and hold the mortar firmly with the left, still on

' the leather pad ; rotate the agate end of the

pestle on the enamel, and go on doing so until

the enamel is pulverised to the finest powder.

Meanwhile the water has become milky, so

pour it away, and add a fresh supply, repeat-

ing this part of the work until the discolora-

tion of the water disappears. Thoroughness

of washing is of the utmost importance in

the preparation of a clear transparent enamel.

Opaque enamels do not require so much

washing.

And now, leaving the enamel corked up

securely in a clean bottle, to prevent any

dust or foreign matter from getting in, let

us see how the metal is prepared. The first

process which I shall describe is that known

as champleve;, the next bassetaille; then

cloisonnd; then painted or Limoges enamels;

and, last of all, miniature painting in enamel.

Champleve enamelling is so called from

the two words champ, a field, and leve,

raised. The field or ground of metal is cut

away, leaving bands of metal to form the

outlines of the design; then with enamel

the part cut away has to be raised flush to

the surface of the outlining bands, so that

the whole is a uniform surface. The first

requirement is a pitch block, that is, a piece

of wood on which a composition of two parts

of pitch, six of plaster, and one of tallow, all

mixed together in a saucepan over the fire,

is poured to the thickness of an inch. In

the case of large work the wood must be

strong and heavy, but when the work is

minute the pitch or cement must be placed

upon the end of a stick.

There are two ways of using the tools, con-

cerning which it is now necessary to speak.

For large work a chaser’s hammer and long steel

chisels must be employed; for small work the graver

or the scooper is held rigidly in the right hand, and

by a firm, restrained pressure the metal is gouged out,

as shown in the illustrations. It is very necessary

to keep the tools sharp and clean. The design is

either drawn on the metal with a hard black lead

point or else transferred upon it by means of transfer

paper in the usual way, and then the lines are

traced with a fine graver, giving a faint hair line

of the utmost exactitude. This done, the line is

cut deeper with a V-shaped tool, about one-thirty-

second of an inch to one-sixteenth, the depth being

governed by the strength of colour required. In

transparent enamelling on silver or gold, for

instance, the darker the colour used the deeper

93