The Art of True Enamelling

a very strong hand to do this. Go once round on

each line, and then start on a fresh one, until you

get to the outer edge; then take the metal to the

blow-pipe and anneal it, softening the metal by

making it red-hot and then letting it cool. All

metals become hard and springy by hammering,

and are softened by heat. After it is cold you

repeat this process of hammering, until a deep

saucer shape is obtained, then turn it over and put

its edge on a curved stake of iron or steel, shaped

conversely, corresponding to the design, and with

well-regulated blows upon the parts immediately

above the stake, go round it, turning it and beating

it at the same time.

After each course of hammering it is necessary

to anneal it, otherwise it will crack and split up >

then continue to hammer in this way until the

shape is complete. To put a cloisonne pattern

upon this, you proceed in the following manner-

The design is drawn or transferred upon the metal,

and then with a steel point is scratched distinctly

upon it, so that the design may be clearly seen

during subsequent processes. The flat wire must

now be thought of for the cloisons. In cloisonne

enamelling on copper it should be of the hardest

brass; silver wire should be used on silver; the

width of the wire is partly determined by the

character of the design and the aim of the artist,

but one-twentieth of an inch thick commonly

suffices for the boldest work. With round and

flat-nosed pliers the wire is bent to the design

and with half the sum of

these as the radius, we

strike a circle on a piece

of silver or copper of 14

metal gauge, then we de-

scribe a number of con-

centric circles, leaving a

quarter of an inch be-

tween each circumference.

Then the edge of the

metal, slightly tilted on the

sandbag, is held firmly in

the left hand, and with a

well-directed blow you

strike it with the end of

the hammer on the first

line from the centre, then,

while moving it slowly

round at the same angle, the

blows are struck regularly

on this line. It requires

114

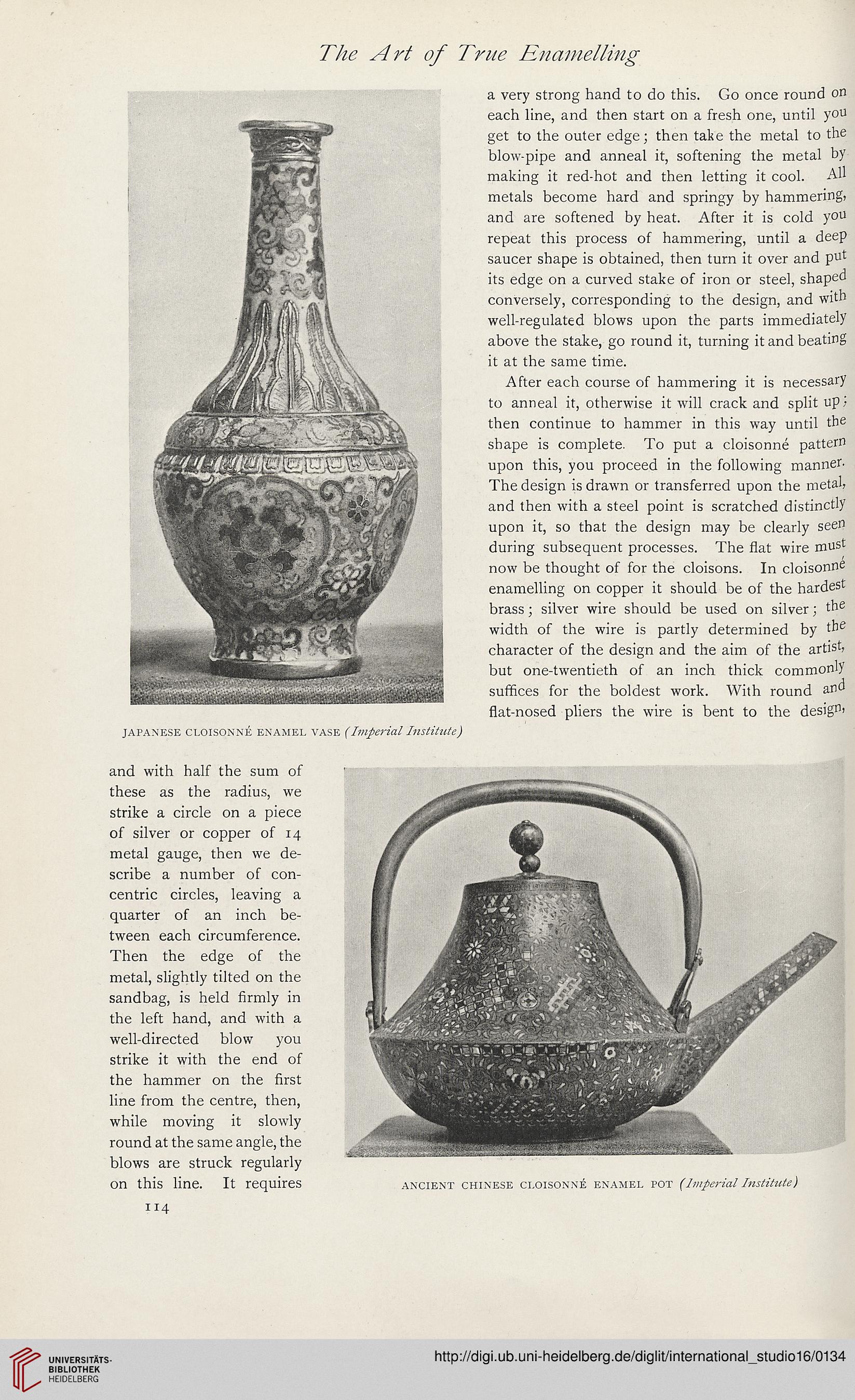

ANCIENT CHINESE CLOISONNE ENAMEL POT (Imperial Institute)

a very strong hand to do this. Go once round on

each line, and then start on a fresh one, until you

get to the outer edge; then take the metal to the

blow-pipe and anneal it, softening the metal by

making it red-hot and then letting it cool. All

metals become hard and springy by hammering,

and are softened by heat. After it is cold you

repeat this process of hammering, until a deep

saucer shape is obtained, then turn it over and put

its edge on a curved stake of iron or steel, shaped

conversely, corresponding to the design, and with

well-regulated blows upon the parts immediately

above the stake, go round it, turning it and beating

it at the same time.

After each course of hammering it is necessary

to anneal it, otherwise it will crack and split up >

then continue to hammer in this way until the

shape is complete. To put a cloisonne pattern

upon this, you proceed in the following manner-

The design is drawn or transferred upon the metal,

and then with a steel point is scratched distinctly

upon it, so that the design may be clearly seen

during subsequent processes. The flat wire must

now be thought of for the cloisons. In cloisonne

enamelling on copper it should be of the hardest

brass; silver wire should be used on silver; the

width of the wire is partly determined by the

character of the design and the aim of the artist,

but one-twentieth of an inch thick commonly

suffices for the boldest work. With round and

flat-nosed pliers the wire is bent to the design

and with half the sum of

these as the radius, we

strike a circle on a piece

of silver or copper of 14

metal gauge, then we de-

scribe a number of con-

centric circles, leaving a

quarter of an inch be-

tween each circumference.

Then the edge of the

metal, slightly tilted on the

sandbag, is held firmly in

the left hand, and with a

well-directed blow you

strike it with the end of

the hammer on the first

line from the centre, then,

while moving it slowly

round at the same angle, the

blows are struck regularly

on this line. It requires

114

ANCIENT CHINESE CLOISONNE ENAMEL POT (Imperial Institute)