The Art of True Enamelling

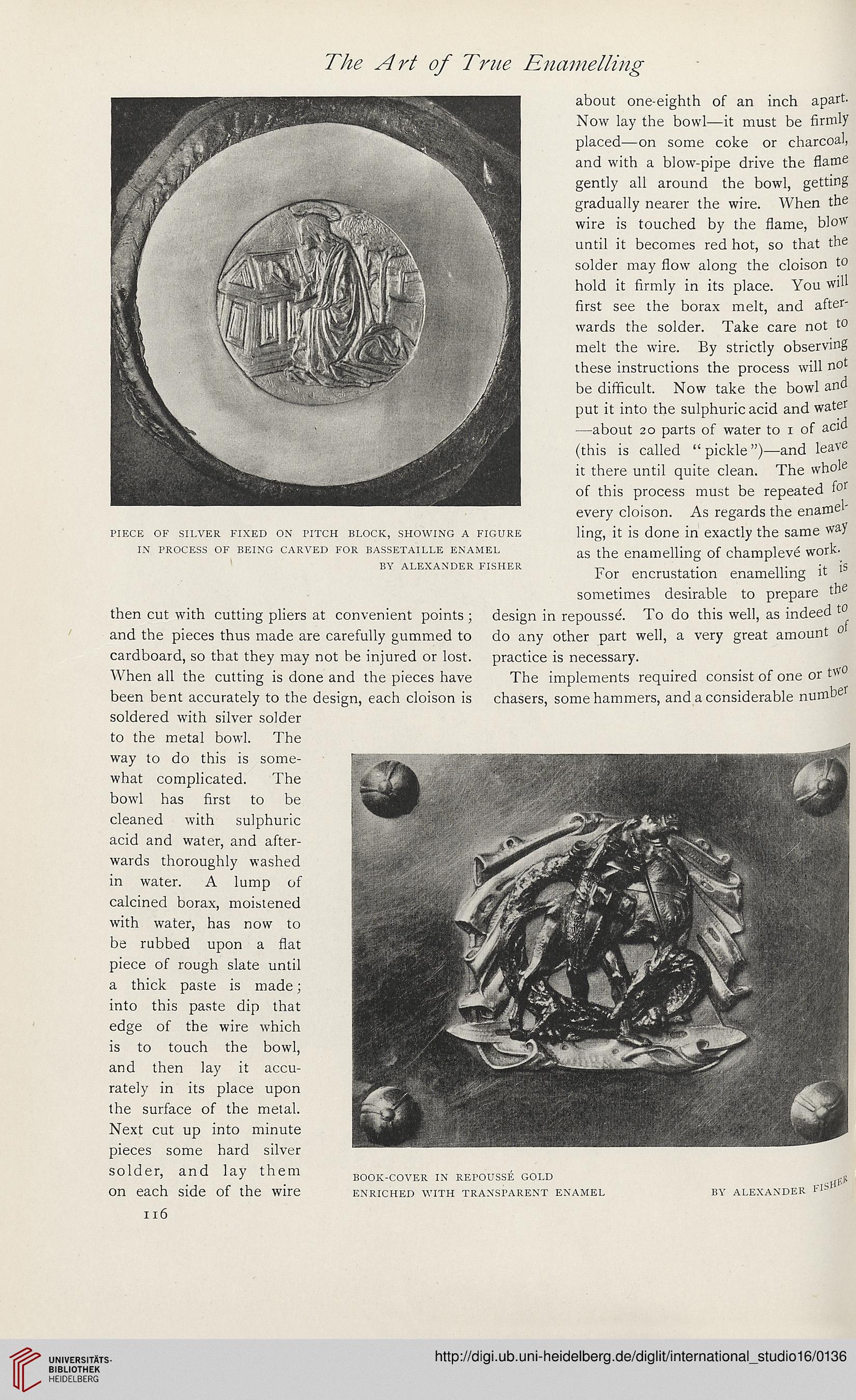

PIECE OF SILVER FIXED ON PITCH BLOCK, SHOWING A FIGURE

IN PROCESS OF BEING CARVED FOR BASSETAILLE ENAMEL

BY ALEXANDER FISHER

about one-eighth of an inch apart-

Now lay the bowl—it must be firmly

placed—on some coke or charcoal,

and with a blow-pipe drive the flame

gently all around the bowl, getting

gradually nearer the wire. When the

wire is touched by the flame, blow

until it becomes red hot, so that the

solder may flow along the cloison to

hold it firmly in its place. You will

first see the borax melt, and after-

wards the solder. Take care not to

melt the wire. By strictly observing

these instructions the process will not

be difficult. Now take the bowl and

put it into the sulphuric acid and water

—about 20 parts of water to i of acid

(this is called “pickle”)—and leave

it there until quite clean. The whole

of this process must be repeated f°r

every cloison. As regards the enamel'

ling, it is done in exactly the same way

as the enamelling of champleve work-

For encrustation enamelling it lS

sometimes desirable to prepare the

then cut with cutting pliers at convenient points; design in repousse. To do this well, as indeed 10

and the pieces thus made are carefully gummed to do any other part well, a very great amount 0

cardboard, so that they may not be injured or lost, practice is necessary.

When all the cutting is done and the pieces have The implements required consist of one or t"°

been bent accurately to the design, each cloison is chasers, some hammers, and a considerable number

soldered with silver solder

to the metal bowl. The

way to do this is some-

what complicated. The

bowl has first to be

cleaned with sulphuric

acid and water, and after-

wards thoroughly washed

in water. A lump of

calcined borax, moistened

with water, has now to

be rubbed upon a flat

piece of rough slate until

a thick paste is made;

into this paste dip that

edge of the wire which

is to touch the bowl,

and then lay it accu-

rately in its place upon

the surface of the metal.

Next cut up into minute

pieces some hard silver

solder, and lay them book-cover in repousse gold

on each side of the wire enriched with transparent enamel by Alexander fis

116

PIECE OF SILVER FIXED ON PITCH BLOCK, SHOWING A FIGURE

IN PROCESS OF BEING CARVED FOR BASSETAILLE ENAMEL

BY ALEXANDER FISHER

about one-eighth of an inch apart-

Now lay the bowl—it must be firmly

placed—on some coke or charcoal,

and with a blow-pipe drive the flame

gently all around the bowl, getting

gradually nearer the wire. When the

wire is touched by the flame, blow

until it becomes red hot, so that the

solder may flow along the cloison to

hold it firmly in its place. You will

first see the borax melt, and after-

wards the solder. Take care not to

melt the wire. By strictly observing

these instructions the process will not

be difficult. Now take the bowl and

put it into the sulphuric acid and water

—about 20 parts of water to i of acid

(this is called “pickle”)—and leave

it there until quite clean. The whole

of this process must be repeated f°r

every cloison. As regards the enamel'

ling, it is done in exactly the same way

as the enamelling of champleve work-

For encrustation enamelling it lS

sometimes desirable to prepare the

then cut with cutting pliers at convenient points; design in repousse. To do this well, as indeed 10

and the pieces thus made are carefully gummed to do any other part well, a very great amount 0

cardboard, so that they may not be injured or lost, practice is necessary.

When all the cutting is done and the pieces have The implements required consist of one or t"°

been bent accurately to the design, each cloison is chasers, some hammers, and a considerable number

soldered with silver solder

to the metal bowl. The

way to do this is some-

what complicated. The

bowl has first to be

cleaned with sulphuric

acid and water, and after-

wards thoroughly washed

in water. A lump of

calcined borax, moistened

with water, has now to

be rubbed upon a flat

piece of rough slate until

a thick paste is made;

into this paste dip that

edge of the wire which

is to touch the bowl,

and then lay it accu-

rately in its place upon

the surface of the metal.

Next cut up into minute

pieces some hard silver

solder, and lay them book-cover in repousse gold

on each side of the wire enriched with transparent enamel by Alexander fis

116