//2'?/As' t7M /M (?/<?/

bowls, soldering to

the bottoms three

small silver balls

for feet. These

balls may be pur-

chased at any jew-

eller's supply

house.

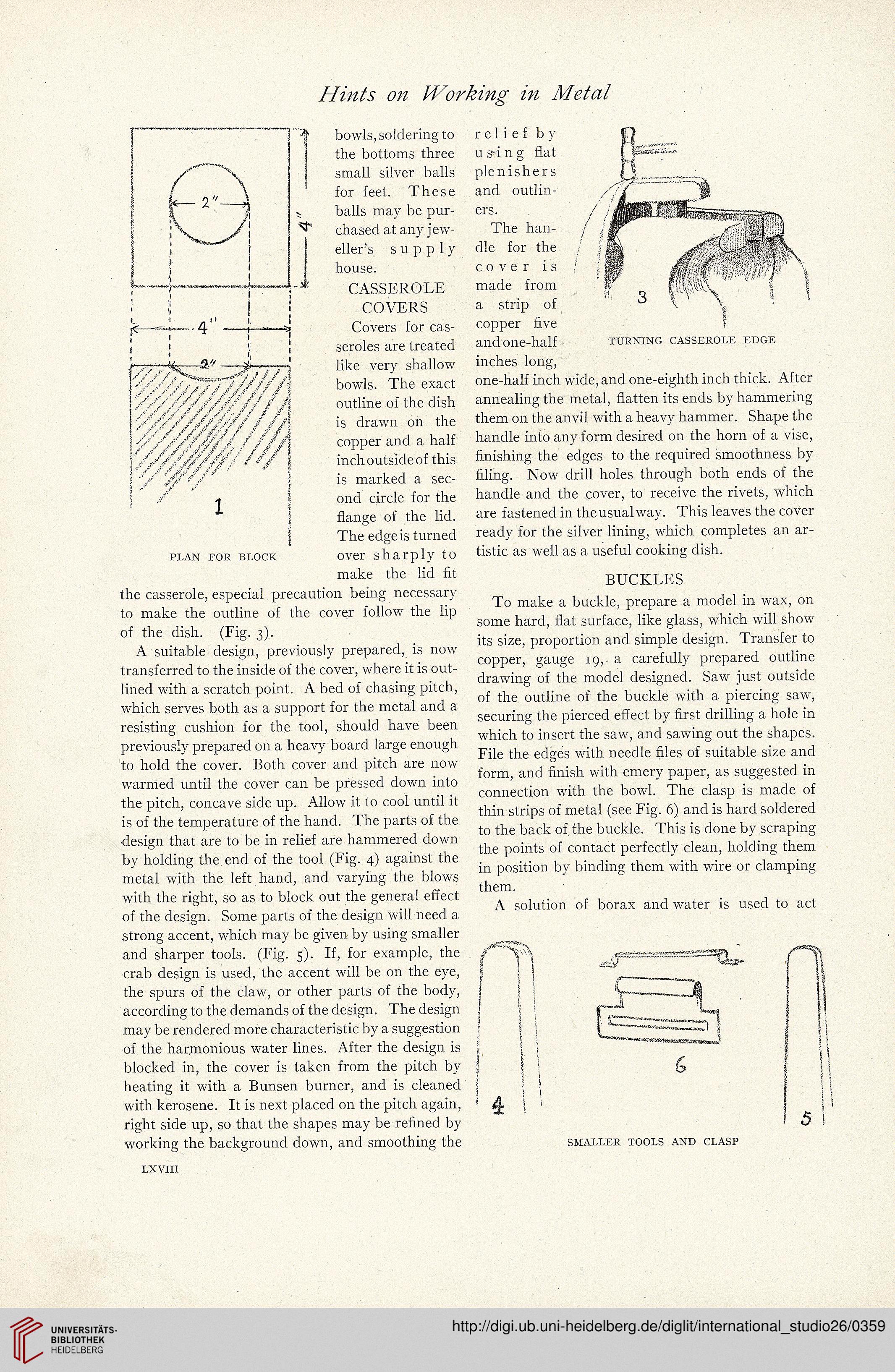

CASSEROLE

COVERS

Covers for cas-

seroles are treated

like very shallow

bowls. The exact

outline of the dish

is drawn on the

copper and a half

inchoutsideofthis

is marked a sec-

ond circle for the

flange of the lid.

The edge is turned

over sharply to

make the lid fit

the casserole, especial precaution being necessary

to make the outline of the cover follow the lip

of the dish. (Fig. 3).

A suitable design, previously prepared, is now

transferred to the inside of the cover, where it is out-

lined with a scratch point. A bed of chasing pitch,

which serves both as a support for the metal and a

resisting cushion for the tool, should have been

previously prepared on a heavy board large enough

to hold the cover. Both cover and pitch are now

warmed until the cover can be pressed down into

the pitch, concave side up. Allow it (o cool until it

is of the temperature of the hand. The parts of the

design that are to be in relief are hammered down

by holding the end of the tool (Fig. 4) against the

metal with the left hand, and varying the blows

with the right, so as to block out the general effect

of the design. Some parts of the design will need a

strong accent, which may be given by using smaller

and sharper tools. (Fig. g). If, for example, the

crab design is used, the accent will be on the eye,

the spurs of the claw, or other parts of the body,

according to the demands of the design. The design

may be rendered more characteristic by a suggestion

of the harmonious water lines. After the design is

blocked in, the cover is taken from the pitch by

heating it with a Bunsen burner, and is cleaned

with kerosene. It is next placed on the pitch again,

right side up, so that the shapes may be refined by

working the background down, and smoothing the

relief by

u s-i n g flat

plenishers

and outlin-

es.

The han-

dle for the

cover is

made from

a strip of

copper five

and one-half TURNING CASSEROLE EDGE

inches long,

one-half inch wide, and one-eighth inch thick. After

annealing the metal, flatten its ends by hammering

them on the anvil with a heavy hammer. Shape the

handle into any form desired on the horn of a vise,

finishing the edges to the required smoothness by

filing. Now drill holes through both ends of the

handle and the cover, to receive the rivets, which

are fastened in the usual way. This leaves the cover

ready for the silver lining, which completes an ar-

tistic as well as a useful cooking dish.

BUCKLES

To make a buckle, prepare a model in wax, on

some hard, flat surface, like glass, which will show

its size, proportion and simple design. Transfer to

copper, gauge 19,. a carefully prepared outline

drawing of the model designed. Saw just outside

of the outline of the buckle with a piercing saw,

securing the pierced effect by first drilling a hole in

which to insert the saw, and sawing out the shapes.

File the edges with needle files of suitable size and

form, and finish with emery paper, as suggested in

connection with the bowl. The clasp is made of

thin strips of metal (see Fig. 6) and is hard soldered

to the back of the buckle. This is done by scraping

the points of contact perfectly clean, holding them

in position by binding them with wire or clamping

them.

A solution of borax and water is used to act

SMALLER TOOLS AND CLASP

PLAN FOR BLOCK

LXVIII

bowls, soldering to

the bottoms three

small silver balls

for feet. These

balls may be pur-

chased at any jew-

eller's supply

house.

CASSEROLE

COVERS

Covers for cas-

seroles are treated

like very shallow

bowls. The exact

outline of the dish

is drawn on the

copper and a half

inchoutsideofthis

is marked a sec-

ond circle for the

flange of the lid.

The edge is turned

over sharply to

make the lid fit

the casserole, especial precaution being necessary

to make the outline of the cover follow the lip

of the dish. (Fig. 3).

A suitable design, previously prepared, is now

transferred to the inside of the cover, where it is out-

lined with a scratch point. A bed of chasing pitch,

which serves both as a support for the metal and a

resisting cushion for the tool, should have been

previously prepared on a heavy board large enough

to hold the cover. Both cover and pitch are now

warmed until the cover can be pressed down into

the pitch, concave side up. Allow it (o cool until it

is of the temperature of the hand. The parts of the

design that are to be in relief are hammered down

by holding the end of the tool (Fig. 4) against the

metal with the left hand, and varying the blows

with the right, so as to block out the general effect

of the design. Some parts of the design will need a

strong accent, which may be given by using smaller

and sharper tools. (Fig. g). If, for example, the

crab design is used, the accent will be on the eye,

the spurs of the claw, or other parts of the body,

according to the demands of the design. The design

may be rendered more characteristic by a suggestion

of the harmonious water lines. After the design is

blocked in, the cover is taken from the pitch by

heating it with a Bunsen burner, and is cleaned

with kerosene. It is next placed on the pitch again,

right side up, so that the shapes may be refined by

working the background down, and smoothing the

relief by

u s-i n g flat

plenishers

and outlin-

es.

The han-

dle for the

cover is

made from

a strip of

copper five

and one-half TURNING CASSEROLE EDGE

inches long,

one-half inch wide, and one-eighth inch thick. After

annealing the metal, flatten its ends by hammering

them on the anvil with a heavy hammer. Shape the

handle into any form desired on the horn of a vise,

finishing the edges to the required smoothness by

filing. Now drill holes through both ends of the

handle and the cover, to receive the rivets, which

are fastened in the usual way. This leaves the cover

ready for the silver lining, which completes an ar-

tistic as well as a useful cooking dish.

BUCKLES

To make a buckle, prepare a model in wax, on

some hard, flat surface, like glass, which will show

its size, proportion and simple design. Transfer to

copper, gauge 19,. a carefully prepared outline

drawing of the model designed. Saw just outside

of the outline of the buckle with a piercing saw,

securing the pierced effect by first drilling a hole in

which to insert the saw, and sawing out the shapes.

File the edges with needle files of suitable size and

form, and finish with emery paper, as suggested in

connection with the bowl. The clasp is made of

thin strips of metal (see Fig. 6) and is hard soldered

to the back of the buckle. This is done by scraping

the points of contact perfectly clean, holding them

in position by binding them with wire or clamping

them.

A solution of borax and water is used to act

SMALLER TOOLS AND CLASP

PLAN FOR BLOCK

LXVIII