THE MANUFACTURES.

25

bone among the earth. The mean diameters of the

circles are 430 and 516 inches, and 1215 and 1343

inches.

50. On examining the dimensions of the buildings

it seems that a usual plan was to fix on some number

of cubits for the hall, and sometimes for the whole

house ; then the chambers were partly determined by

even numbers of cubits, and partly by resultant

quantities involving the thickness of the walls.

The bricks varied in size ; but they, were never even

divisions of the cubit, so as to make the walls work

in with the cubit. From 12 to 15 inches long, and

half as wide was the usual size for bricks. The

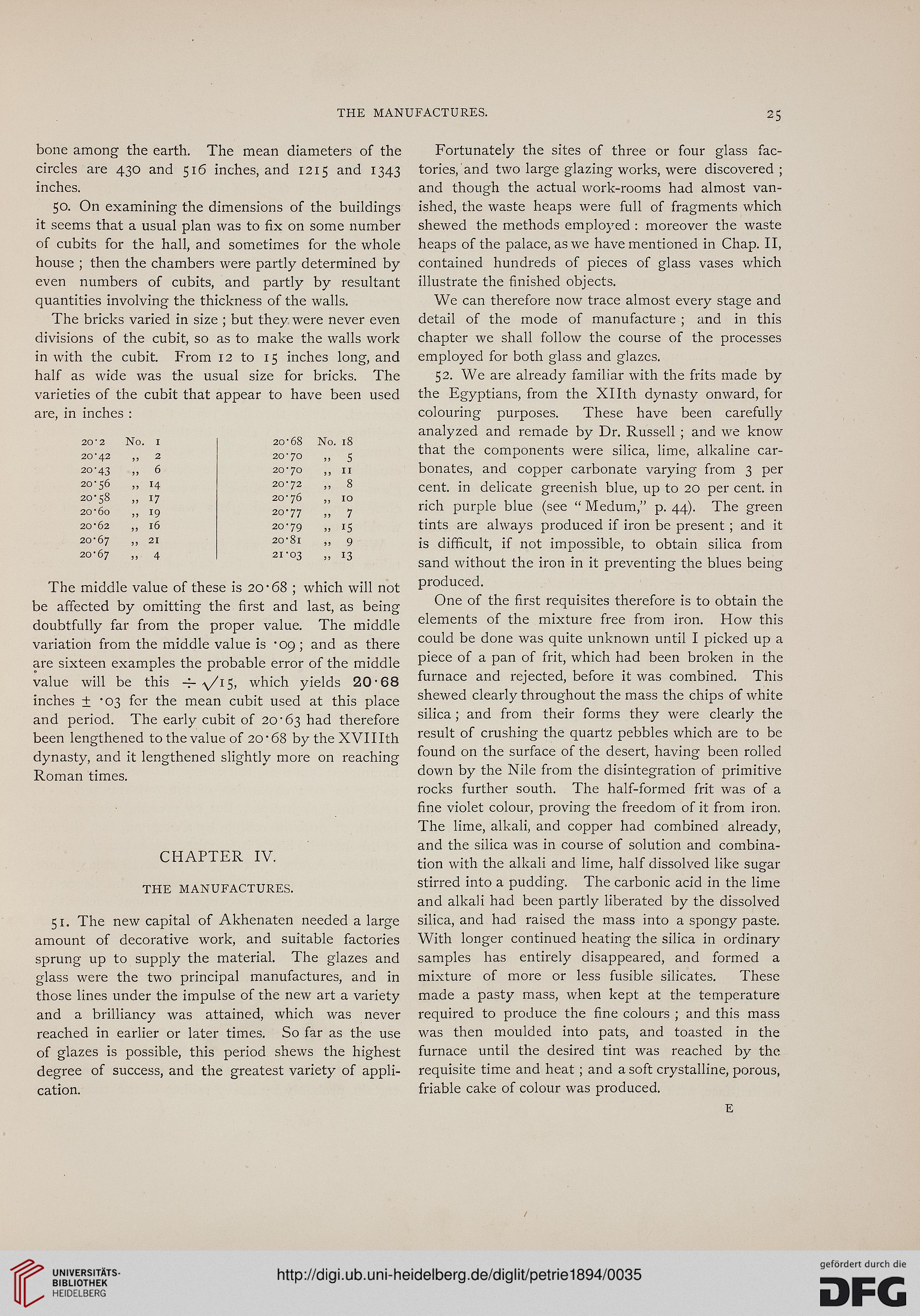

varieties of the cubit that appear to have been used

are, in inches :

20 • 2

No.

I

20-68

No. 18

20-42

>)

2

20-70

5

20-43

6

20-70

33 n

20-56

j >

14

20-72

,. 8

20-58

?>

17

20-76

33 10

20" 60

j>

19

20-77

„ 7

20"62

33

16

20-79

.3 15

20-67

33

21

20-81

» 9

20-67

J3

4

21-03

„ 13

The middle value of these is 20 "68 ; which will not

be affected by omitting the first and last, as being

doubtfully far from the proper value. The middle

variation from the middle value is -09 ; and as there

are sixteen examples the probable error of the middle

value will be this ~ 5, which yields 20 ■ 68

inches ± -03 for the mean cubit used at this place

and period. The early cubit of 20-63 had therefore

been lengthened to the value of 20*68 by the XVIIIth

dynasty, and it lengthened slightly more on reaching

Roman times.

CHAPTER IV.

THE MANUFACTURES.

51. The new capital of Akhenaten needed a large

amount of decorative work, and suitable factories

sprung up to supply the material. The glazes and

glass were the two principal manufactures, and in

those lines under the impulse of the new art a variety

and a brilliancy was attained, which was never

reached in earlier or later times. So far as the use

of glazes is possible, this period shews the highest

degree of success, and the greatest variety of appli-

cation.

Fortunately the sites of three or four glass fac-

tories, and two large glazing works, were discovered ;

and though the actual work-rooms had almost van-

ished, the waste heaps were full of fragments which

shewed the methods employed : moreover the waste

heaps of the palace, as we have mentioned in Chap. II,

contained hundreds of pieces of glass vases which

illustrate the finished objects.

We can therefore now trace almost every stage and

detail of the mode of manufacture ; and in this

chapter we shall follow the course of the processes

employed for both glass and glazes.

52. We are already familiar with the frits made by

the Egyptians, from the Xllth dynasty onward, for

colouring purposes. These have been carefully

analyzed and remade by Dr. Russell ; and we know

that the components were silica, lime, alkaline car-

bonates, and copper carbonate varying from 3 per

cent, in delicate greenish blue, up to 20 per cent, in

rich purple blue (see " Medum," p. 44). The green

tints are always produced if iron be present ; and it

is difficult, if not impossible, to obtain silica from

sand without the iron in it preventing the blues being

produced.

One of the first requisites therefore is to obtain the

elements of the mixture free from iron. How this

could be done was quite unknown until I picked up a

piece of a pan of frit, which had been broken in the

furnace and rejected, before it was combined. This

shewed clearly throughout the mass the chips of white

silica; and from their forms they were clearly the

result of crushing the quartz pebbles which are to be

found on the surface of the desert, having been rolled

down by the Nile from the disintegration of primitive

rocks further south. The half-formed frit was of a

fine violet colour, proving the freedom of it from iron.

The lime, alkali, and copper had combined already,

and the silica was in course of solution and combina-

tion with the alkali and lime, half dissolved like sugar

stirred into a pudding. The carbonic acid in the lime

and alkali had been partly liberated by the dissolved

silica, and had raised the mass into a spongy paste.

With longer continued heating the silica in ordinary

samples has entirely disappeared, and formed a

mixture of more or less fusible silicates. These

made a pasty mass, when kept at the temperature

required to produce the fine colours ; and this mass

was then moulded into pats, and toasted in the

furnace until the desired tint was reached by the

requisite time and heat ; and a soft crystalline, porous,

friable cake of colour was produced.

E

/

25

bone among the earth. The mean diameters of the

circles are 430 and 516 inches, and 1215 and 1343

inches.

50. On examining the dimensions of the buildings

it seems that a usual plan was to fix on some number

of cubits for the hall, and sometimes for the whole

house ; then the chambers were partly determined by

even numbers of cubits, and partly by resultant

quantities involving the thickness of the walls.

The bricks varied in size ; but they, were never even

divisions of the cubit, so as to make the walls work

in with the cubit. From 12 to 15 inches long, and

half as wide was the usual size for bricks. The

varieties of the cubit that appear to have been used

are, in inches :

20 • 2

No.

I

20-68

No. 18

20-42

>)

2

20-70

5

20-43

6

20-70

33 n

20-56

j >

14

20-72

,. 8

20-58

?>

17

20-76

33 10

20" 60

j>

19

20-77

„ 7

20"62

33

16

20-79

.3 15

20-67

33

21

20-81

» 9

20-67

J3

4

21-03

„ 13

The middle value of these is 20 "68 ; which will not

be affected by omitting the first and last, as being

doubtfully far from the proper value. The middle

variation from the middle value is -09 ; and as there

are sixteen examples the probable error of the middle

value will be this ~ 5, which yields 20 ■ 68

inches ± -03 for the mean cubit used at this place

and period. The early cubit of 20-63 had therefore

been lengthened to the value of 20*68 by the XVIIIth

dynasty, and it lengthened slightly more on reaching

Roman times.

CHAPTER IV.

THE MANUFACTURES.

51. The new capital of Akhenaten needed a large

amount of decorative work, and suitable factories

sprung up to supply the material. The glazes and

glass were the two principal manufactures, and in

those lines under the impulse of the new art a variety

and a brilliancy was attained, which was never

reached in earlier or later times. So far as the use

of glazes is possible, this period shews the highest

degree of success, and the greatest variety of appli-

cation.

Fortunately the sites of three or four glass fac-

tories, and two large glazing works, were discovered ;

and though the actual work-rooms had almost van-

ished, the waste heaps were full of fragments which

shewed the methods employed : moreover the waste

heaps of the palace, as we have mentioned in Chap. II,

contained hundreds of pieces of glass vases which

illustrate the finished objects.

We can therefore now trace almost every stage and

detail of the mode of manufacture ; and in this

chapter we shall follow the course of the processes

employed for both glass and glazes.

52. We are already familiar with the frits made by

the Egyptians, from the Xllth dynasty onward, for

colouring purposes. These have been carefully

analyzed and remade by Dr. Russell ; and we know

that the components were silica, lime, alkaline car-

bonates, and copper carbonate varying from 3 per

cent, in delicate greenish blue, up to 20 per cent, in

rich purple blue (see " Medum," p. 44). The green

tints are always produced if iron be present ; and it

is difficult, if not impossible, to obtain silica from

sand without the iron in it preventing the blues being

produced.

One of the first requisites therefore is to obtain the

elements of the mixture free from iron. How this

could be done was quite unknown until I picked up a

piece of a pan of frit, which had been broken in the

furnace and rejected, before it was combined. This

shewed clearly throughout the mass the chips of white

silica; and from their forms they were clearly the

result of crushing the quartz pebbles which are to be

found on the surface of the desert, having been rolled

down by the Nile from the disintegration of primitive

rocks further south. The half-formed frit was of a

fine violet colour, proving the freedom of it from iron.

The lime, alkali, and copper had combined already,

and the silica was in course of solution and combina-

tion with the alkali and lime, half dissolved like sugar

stirred into a pudding. The carbonic acid in the lime

and alkali had been partly liberated by the dissolved

silica, and had raised the mass into a spongy paste.

With longer continued heating the silica in ordinary

samples has entirely disappeared, and formed a

mixture of more or less fusible silicates. These

made a pasty mass, when kept at the temperature

required to produce the fine colours ; and this mass

was then moulded into pats, and toasted in the

furnace until the desired tint was reached by the

requisite time and heat ; and a soft crystalline, porous,

friable cake of colour was produced.

E

/