The Making of Plaster Casts

be done in plaster piece-moulds, wax or

gelatine moulds. Plaster piece-moulds

are generally used for casting figures in

the round. The mould is put on in

sections (hence the name), so that every

piece will draw from its own surface.

There may be a considerable number

of pieces, all held together by each part

being locked into the other. For in-

stance, a bust may consist of about

seventy pieces. The casting is done as

in waste moulds, except that in round

figures the mould must be continually

rolled over and over as the plaster is

filled in, so that the finished production

may be hollow with an even thickness

all over. The mould can be removed

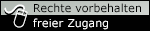

FIG. 4.—CHIPPING THE WASTE MOULD

accordingly proceeds all

the more carefully. Thus

the mould can be used

once only — hence the

term waste mould (Fig. 3).

The castings are now

removed to the drying

chamber (Fig. 5), where

the temperature is about

100 degrees. Care must

be exercised at this stage,

and the exposure regu-

lated according to circum-

stances.

Repeat casting can only

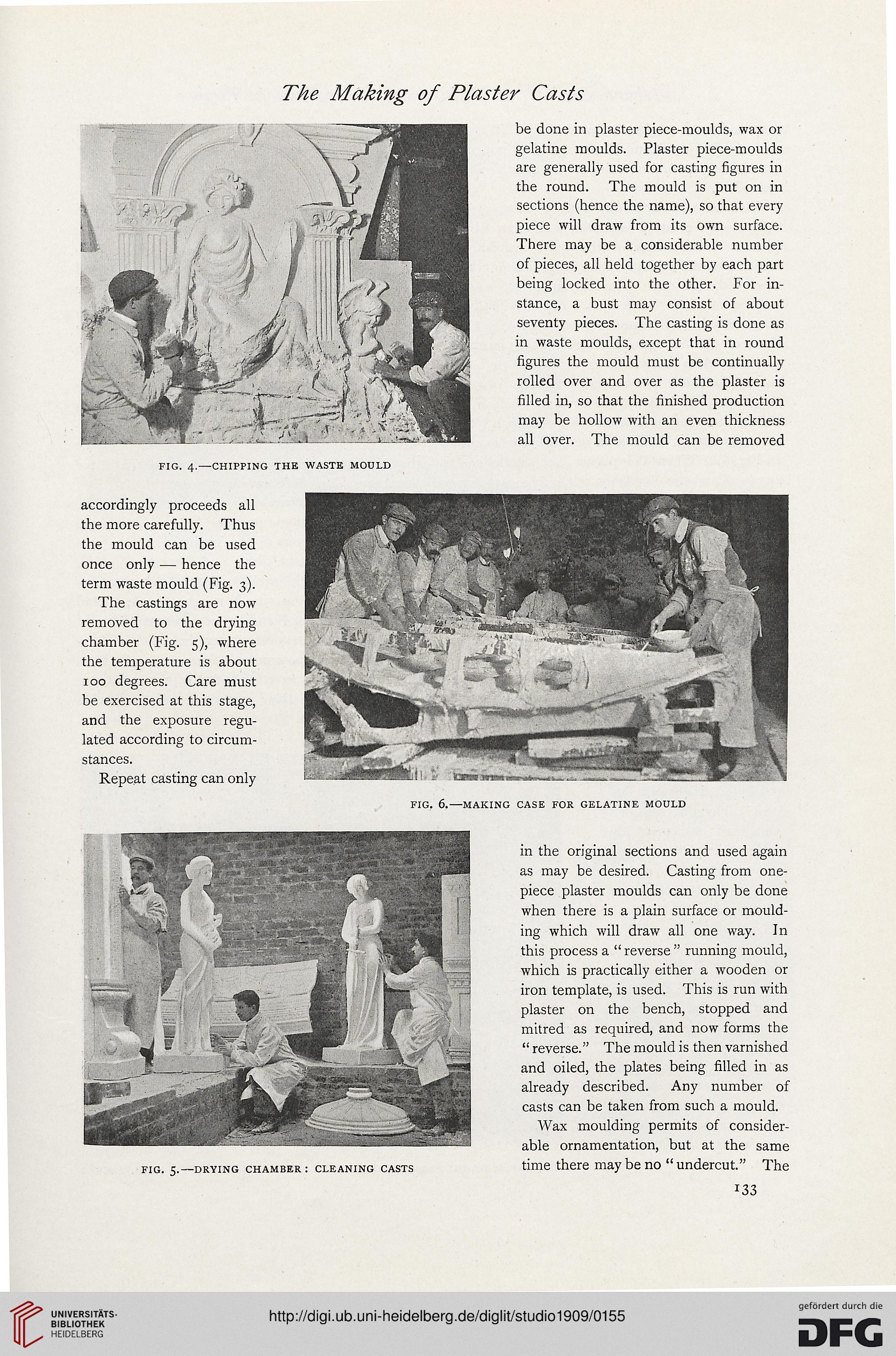

FIG. 6.—MAKING CASE FOR GELATINE MOULD

FIG. 5.—DRYING CHAMBER: CLEANING CASTS

in the original sections and used again

as may be desired. Casting from one-

piece plaster moulds can only be done

when there is a plain surface or mould-

ing which will draw all one way. In

this process a “reverse” running mould,

which is practically either a wooden or

iron template, is used. This is run with

plaster on the bench, stopped and

mitred as required, and now forms the

“ reverse.” The mould is then varnished

and oiled, the plates being filled in as

already described. Any number of

casts can be taken from such a mould.

Wax moulding permits of consider-

able ornamentation, but at the same

time there may be no “ undercut.” The

!33

be done in plaster piece-moulds, wax or

gelatine moulds. Plaster piece-moulds

are generally used for casting figures in

the round. The mould is put on in

sections (hence the name), so that every

piece will draw from its own surface.

There may be a considerable number

of pieces, all held together by each part

being locked into the other. For in-

stance, a bust may consist of about

seventy pieces. The casting is done as

in waste moulds, except that in round

figures the mould must be continually

rolled over and over as the plaster is

filled in, so that the finished production

may be hollow with an even thickness

all over. The mould can be removed

FIG. 4.—CHIPPING THE WASTE MOULD

accordingly proceeds all

the more carefully. Thus

the mould can be used

once only — hence the

term waste mould (Fig. 3).

The castings are now

removed to the drying

chamber (Fig. 5), where

the temperature is about

100 degrees. Care must

be exercised at this stage,

and the exposure regu-

lated according to circum-

stances.

Repeat casting can only

FIG. 6.—MAKING CASE FOR GELATINE MOULD

FIG. 5.—DRYING CHAMBER: CLEANING CASTS

in the original sections and used again

as may be desired. Casting from one-

piece plaster moulds can only be done

when there is a plain surface or mould-

ing which will draw all one way. In

this process a “reverse” running mould,

which is practically either a wooden or

iron template, is used. This is run with

plaster on the bench, stopped and

mitred as required, and now forms the

“ reverse.” The mould is then varnished

and oiled, the plates being filled in as

already described. Any number of

casts can be taken from such a mould.

Wax moulding permits of consider-

able ornamentation, but at the same

time there may be no “ undercut.” The

!33