Leather Embossing

and remained lost up to the first half of this

century, when a revival took place in Germany.

Its disappearance is understood when one calls to

mind the practice of substituting inferior imitations

of costly materials that has degraded almost all

crafts in modern times. It is quite possible to

52

imagine that an artist who spent his time and

energy in embossing and otherwise decorating

leather, would feel hardly grateful to an enterprising,

manufacturer who produced a caricature of his-

creations in papier-mache.

The four or five artists who are responsible for

the revival of the craft in Germany, have met their

reward in that country; one of them, Mr. H.

Jacobsen, whose work is the special theme of this

article, is now trying to give an impetus to the

craft in England, both by teaching and producing.

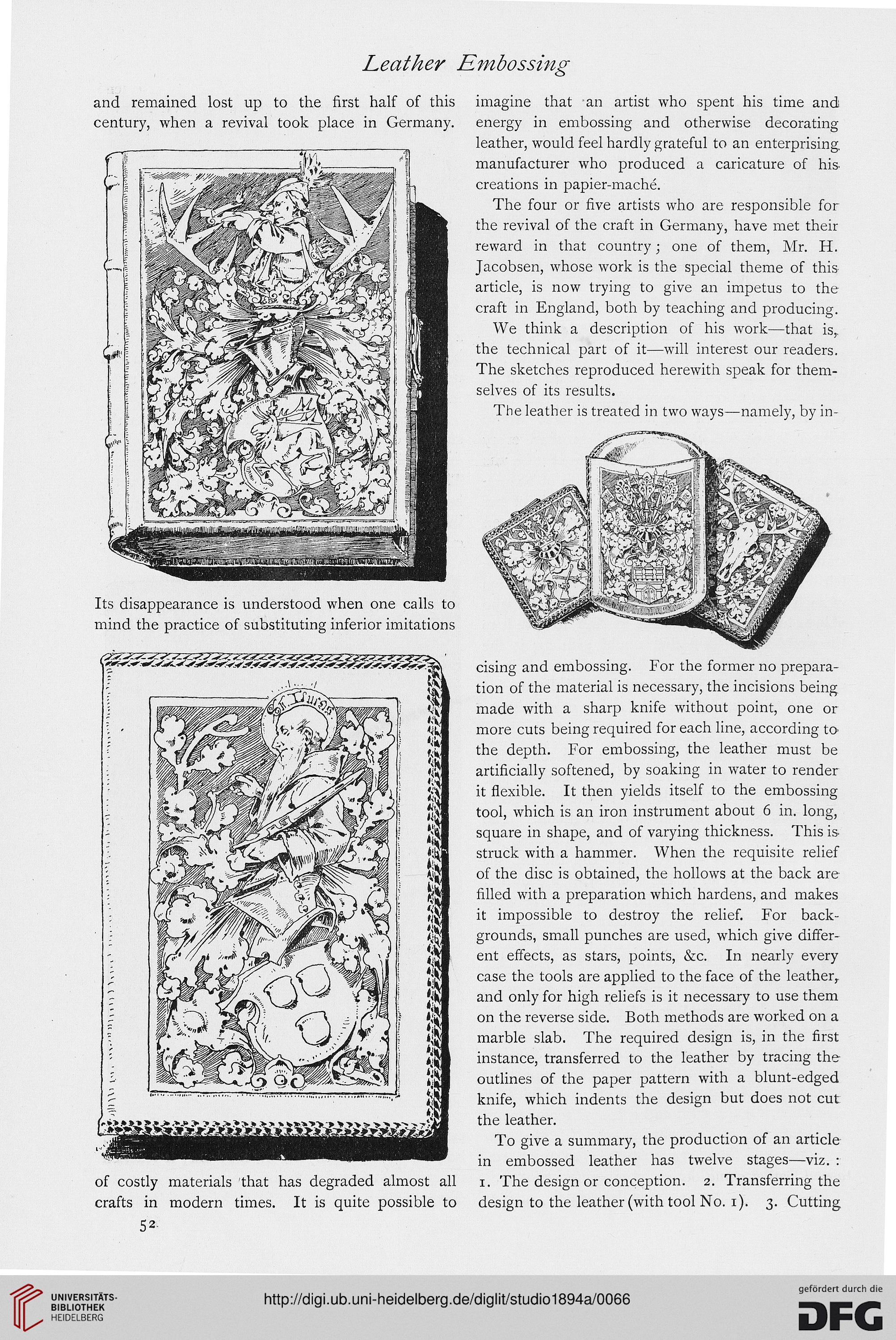

We think a description of his work—that is,,

the technical part of it—will interest our readers.

The sketches reproduced herewith speak for them-

selves of its results.

The leather is treated in two ways—namely, by in-

cising and embossing. For the former no prepara-

tion of the material is necessary, the incisions being

made with a sharp knife without point, one or

more cuts being required for each line, according to

the depth. For embossing, the leather must be

artificially softened, by soaking in water to render

it flexible. It then yields itself to the embossing

tool, which is an iron instrument about 6 in. long,

square in shape, and of varying thickness. This is-

struck with a hammer. When the requisite relief

of the disc is obtained, the hollows at the back are

filled with a preparation which hardens, and makes

it impossible to destroy the relief. For back-

grounds, small punches are used, which give differ-

ent effects, as stars, points, &c. In nearly every

case the tools are applied to the face of the leatherr

and only for high reliefs is it necessary to use them

on the reverse side. Both methods are worked on a

marble slab. The required design is, in the first

instance, transferred to the leather by tracing the

outlines of the paper pattern with a blunt-edged

knife, which indents the design but does not cut

the leather.

To give a summary, the production of an article

in embossed leather has twelve stages—viz. :

1. The design or conception. 2. Transferring the

design to the leather (with tool No. 1). 3. Cutting

and remained lost up to the first half of this

century, when a revival took place in Germany.

Its disappearance is understood when one calls to

mind the practice of substituting inferior imitations

of costly materials that has degraded almost all

crafts in modern times. It is quite possible to

52

imagine that an artist who spent his time and

energy in embossing and otherwise decorating

leather, would feel hardly grateful to an enterprising,

manufacturer who produced a caricature of his-

creations in papier-mache.

The four or five artists who are responsible for

the revival of the craft in Germany, have met their

reward in that country; one of them, Mr. H.

Jacobsen, whose work is the special theme of this

article, is now trying to give an impetus to the

craft in England, both by teaching and producing.

We think a description of his work—that is,,

the technical part of it—will interest our readers.

The sketches reproduced herewith speak for them-

selves of its results.

The leather is treated in two ways—namely, by in-

cising and embossing. For the former no prepara-

tion of the material is necessary, the incisions being

made with a sharp knife without point, one or

more cuts being required for each line, according to

the depth. For embossing, the leather must be

artificially softened, by soaking in water to render

it flexible. It then yields itself to the embossing

tool, which is an iron instrument about 6 in. long,

square in shape, and of varying thickness. This is-

struck with a hammer. When the requisite relief

of the disc is obtained, the hollows at the back are

filled with a preparation which hardens, and makes

it impossible to destroy the relief. For back-

grounds, small punches are used, which give differ-

ent effects, as stars, points, &c. In nearly every

case the tools are applied to the face of the leatherr

and only for high reliefs is it necessary to use them

on the reverse side. Both methods are worked on a

marble slab. The required design is, in the first

instance, transferred to the leather by tracing the

outlines of the paper pattern with a blunt-edged

knife, which indents the design but does not cut

the leather.

To give a summary, the production of an article

in embossed leather has twelve stages—viz. :

1. The design or conception. 2. Transferring the

design to the leather (with tool No. 1). 3. Cutting