Painted Enamels

Further, the idea that without these cells the portion to the size of the plate, within the edge of

enamel would fly off the metal was seen to be the metal from point to point, while the plate is

a mistake. On the contrary, it was discovered held at an angle of 45 degrees to the surface plate,

that there was no necessity for these cloisons—for This line is carried round the other edges of the

they were of no technical value. It goes without plate, and then the burnisher is rubbed across

saying that any enamel can be made to flow by it repeatedly in every direction within this line,

excessive heat, just as the metal upon which the until the plate assumes a form in section thus :

enamel is fired can be melted, as many beginners _ --1—' -

unhappily discover. But with due care and ex- through the middle; while the edges lie perfectly

perience, there is no danger of such an event level with the surface plate. After this has been

occurring. There are several conditions which done—and, perhaps, to get it true it may be

successful enamelling demands. They are of the necessary to anneal it several times — it is

utmost importance, and therefore I place them cleaned by being placed in a glazed porcelain

first, before describing any of the processes bath containing a mixture of sulphuric acid

employed in the making of painted enamels, and water, in the proportion of 1 to 20 parts.

They are as follows: use hard enamels, and pure Then it is washed in water, and afterwards it

or almost pure metals, and pure water, i.e. is either dipped into strong ?aqua fortis, plunged

chemically pure. Further, great cleanliness must be into water to wash the acid off, and dried

exercised: clean metals,

clean tools and brushes,

clean saucers, pots and

planches—a clean fur-

nace, and above all, clean,

freshly-ground enamels.

Painted enamels are gen-

erally done upon copper.

And for this purpose thin

pure copper is the best.

The copper is cut with

shears to the required

shape and size, and then

it is raised to a shallow

. bombe form, so that the

plate of metal rests upon

its edges, leaving the

underneath side free of

the planche upon which

it is subsequently placed

for firing. The reason

of this is, that the

convexity helps to main-

tain the shape of the

plate and prevents it

warping in the fur-

nace. It is made convex

with steel or hematite

burnishers, such as were

shown in a previous

illustration (Article No.

III.). The burnisher

is pressed along a

curved line, varying from

one-quarter of an inch

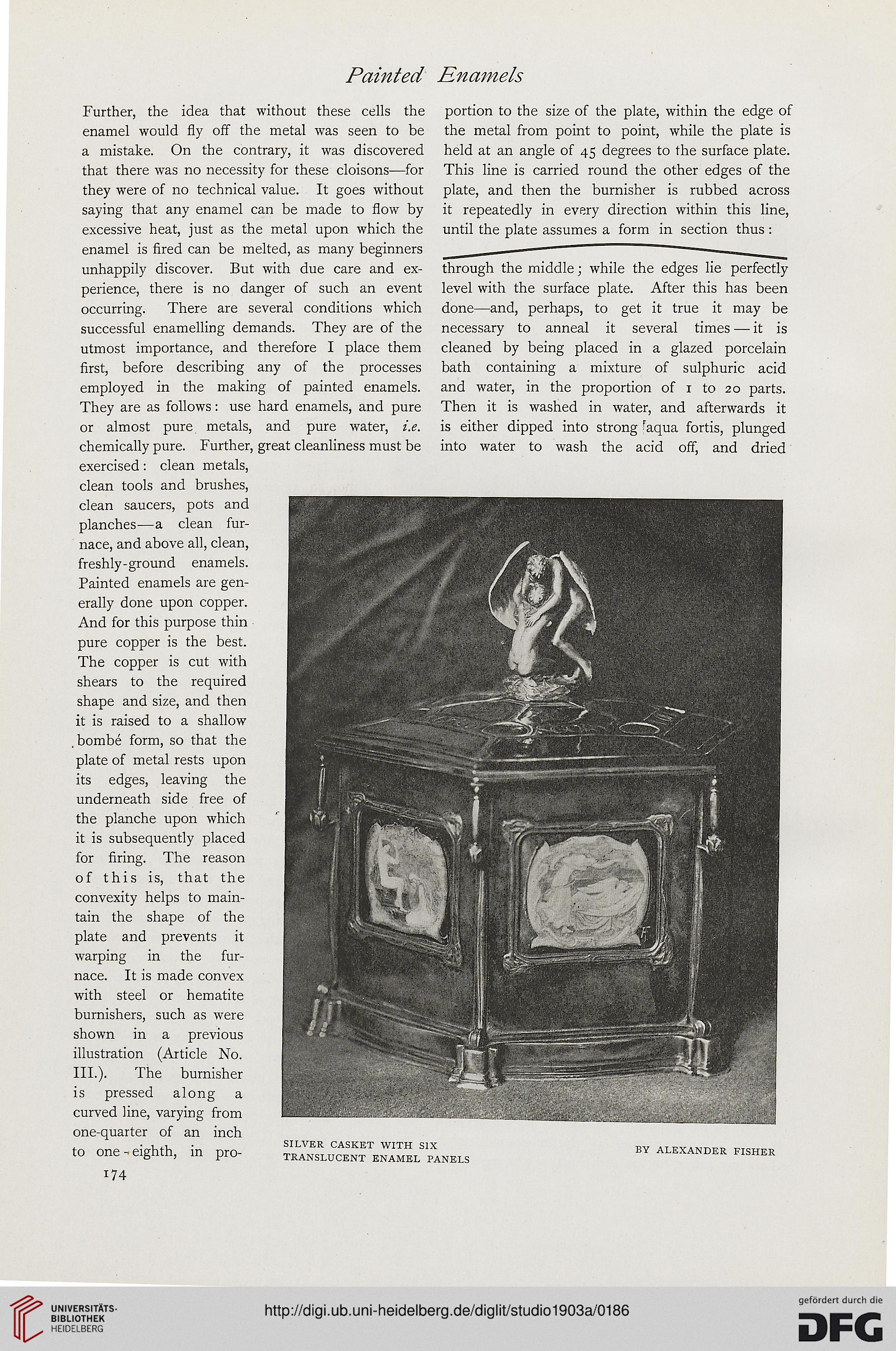

to one-eighth, in pro- SSL^^'?™ ^ Alexander fisher

174

Further, the idea that without these cells the portion to the size of the plate, within the edge of

enamel would fly off the metal was seen to be the metal from point to point, while the plate is

a mistake. On the contrary, it was discovered held at an angle of 45 degrees to the surface plate,

that there was no necessity for these cloisons—for This line is carried round the other edges of the

they were of no technical value. It goes without plate, and then the burnisher is rubbed across

saying that any enamel can be made to flow by it repeatedly in every direction within this line,

excessive heat, just as the metal upon which the until the plate assumes a form in section thus :

enamel is fired can be melted, as many beginners _ --1—' -

unhappily discover. But with due care and ex- through the middle; while the edges lie perfectly

perience, there is no danger of such an event level with the surface plate. After this has been

occurring. There are several conditions which done—and, perhaps, to get it true it may be

successful enamelling demands. They are of the necessary to anneal it several times — it is

utmost importance, and therefore I place them cleaned by being placed in a glazed porcelain

first, before describing any of the processes bath containing a mixture of sulphuric acid

employed in the making of painted enamels, and water, in the proportion of 1 to 20 parts.

They are as follows: use hard enamels, and pure Then it is washed in water, and afterwards it

or almost pure metals, and pure water, i.e. is either dipped into strong ?aqua fortis, plunged

chemically pure. Further, great cleanliness must be into water to wash the acid off, and dried

exercised: clean metals,

clean tools and brushes,

clean saucers, pots and

planches—a clean fur-

nace, and above all, clean,

freshly-ground enamels.

Painted enamels are gen-

erally done upon copper.

And for this purpose thin

pure copper is the best.

The copper is cut with

shears to the required

shape and size, and then

it is raised to a shallow

. bombe form, so that the

plate of metal rests upon

its edges, leaving the

underneath side free of

the planche upon which

it is subsequently placed

for firing. The reason

of this is, that the

convexity helps to main-

tain the shape of the

plate and prevents it

warping in the fur-

nace. It is made convex

with steel or hematite

burnishers, such as were

shown in a previous

illustration (Article No.

III.). The burnisher

is pressed along a

curved line, varying from

one-quarter of an inch

to one-eighth, in pro- SSL^^'?™ ^ Alexander fisher

174