Enamelling

the cutting ought to be—

within limits, of course—

one-sixteenth being quite

deep enough for an object of

any size. When this depth

is exceeded the enamel is

so thick that it flies off. A

trench having thus been

chiselled all around the

spaces, leaving the line of

design untouched, the

spaces themselves have to

be cut to an equal surface,

at the same depth as the

surrounding trench—that

is, one-thirty-second or one-

sixteenth of an inch below

their present surface. The

metal ought to be fairly

thick, either No. 14 or 16

metal gauge, and for larger chiselling cells in the border of a frame for the insertion of enamel

pieces No. 18 or 20 metal

gauge.

This surface, which has been chiselled or gentle heat from a blow-pipe flame. The back is

"scorped," must now be cut into a roughened cleaned thoroughly with paraffin, and then treated

surface, so as to give it a strong key for the enamel with a hot solution of crystal soda, after which it is

to hold on by. Many varieties of textures and finally cleaned with methylated spirits. Then, upon

patterns may be given to this keying of the surface, the parts which are cut out, the chosen enamels,

which in the case of transparent enamels is of mixed with distilled water, are laid with a small

very great importance. spatula. If the piece of work is large, and

As soon as the surface is well keyed, the metal may take several days or weeks to fill in, it

plate is taken off the pitch by means of a very is better to add a few drops of a weak solution

of gum tragacanth or of

quince-pips, so that those

parts which are set and

dry may not be disturbed

by the subsequent filling-

in of other parts. This

being finished, it is neces-

sary to fire— that is, to

fuse the enamel. For this

purpose I find that a gas

furnace is greatly superior

to any other kind. It is

cleaner, it requires less

attention, and it gives a

more uniform heat, and in

many ways saves a good

deal of time. If, however,

gas cannot be obtained, a

furnace heated by coke or

by petroleum is sufficiently

serviceable. Besides a

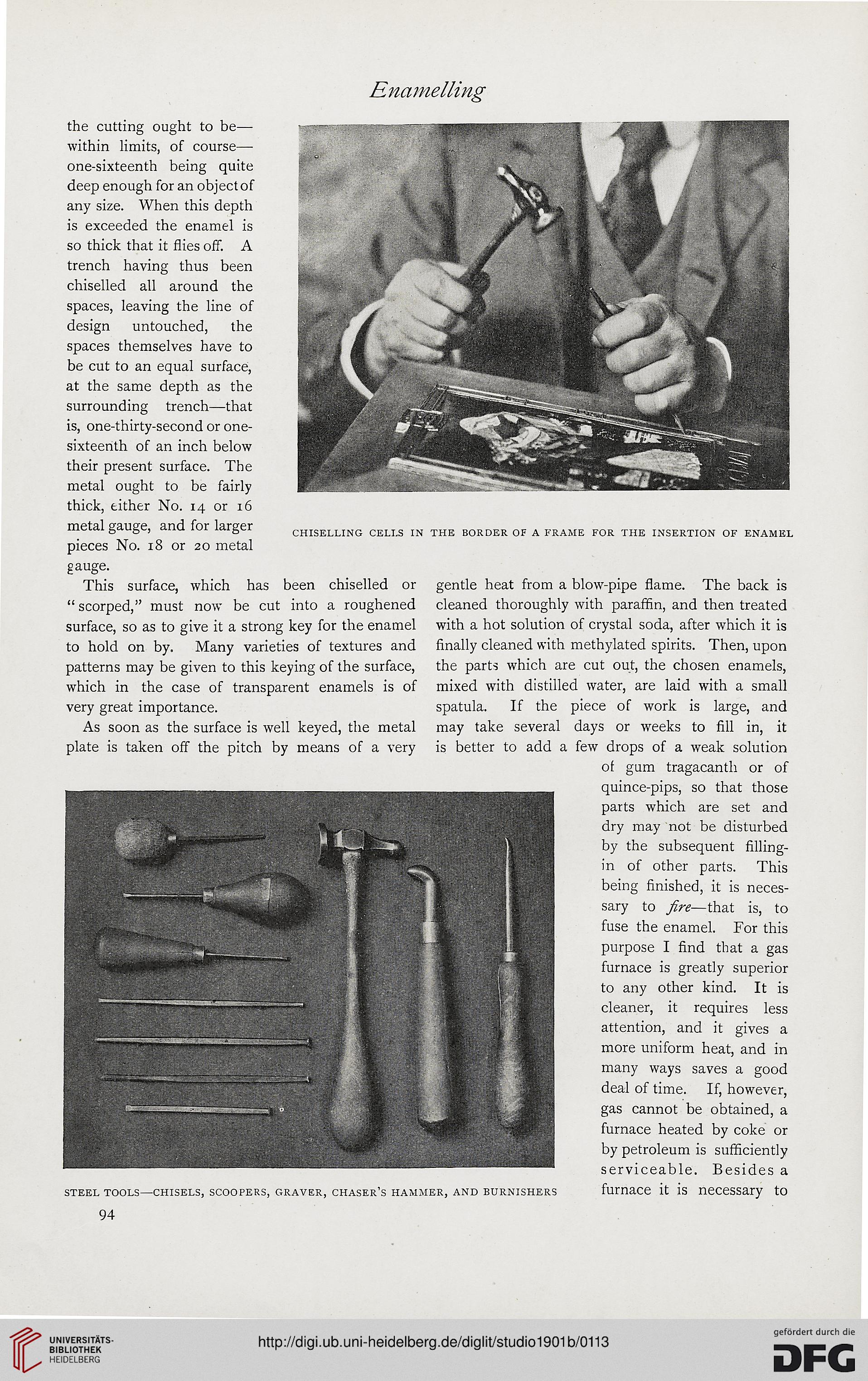

steel tools—chisels, scoopers, graver, chaser's hammer, and burnishers furnace it is necessary to

94

the cutting ought to be—

within limits, of course—

one-sixteenth being quite

deep enough for an object of

any size. When this depth

is exceeded the enamel is

so thick that it flies off. A

trench having thus been

chiselled all around the

spaces, leaving the line of

design untouched, the

spaces themselves have to

be cut to an equal surface,

at the same depth as the

surrounding trench—that

is, one-thirty-second or one-

sixteenth of an inch below

their present surface. The

metal ought to be fairly

thick, either No. 14 or 16

metal gauge, and for larger chiselling cells in the border of a frame for the insertion of enamel

pieces No. 18 or 20 metal

gauge.

This surface, which has been chiselled or gentle heat from a blow-pipe flame. The back is

"scorped," must now be cut into a roughened cleaned thoroughly with paraffin, and then treated

surface, so as to give it a strong key for the enamel with a hot solution of crystal soda, after which it is

to hold on by. Many varieties of textures and finally cleaned with methylated spirits. Then, upon

patterns may be given to this keying of the surface, the parts which are cut out, the chosen enamels,

which in the case of transparent enamels is of mixed with distilled water, are laid with a small

very great importance. spatula. If the piece of work is large, and

As soon as the surface is well keyed, the metal may take several days or weeks to fill in, it

plate is taken off the pitch by means of a very is better to add a few drops of a weak solution

of gum tragacanth or of

quince-pips, so that those

parts which are set and

dry may not be disturbed

by the subsequent filling-

in of other parts. This

being finished, it is neces-

sary to fire— that is, to

fuse the enamel. For this

purpose I find that a gas

furnace is greatly superior

to any other kind. It is

cleaner, it requires less

attention, and it gives a

more uniform heat, and in

many ways saves a good

deal of time. If, however,

gas cannot be obtained, a

furnace heated by coke or

by petroleum is sufficiently

serviceable. Besides a

steel tools—chisels, scoopers, graver, chaser's hammer, and burnishers furnace it is necessary to

94