Enamelling

have supports or "planches"

for holding the enamelled

metal plate. These may

be made of iron, coated

with chalk, loam, silica, or

rouge; or they may be

of fireclay, coated with the

same substances. It is

better to heat the "planche '

before placing the enamelled

plate upon it ready for the

furnace. The tongs should

be long and firm, with long,

thin, pointed fingers.

When the muffle of the

furnace has reached a

pale orange red, the second

part of the process begins.

It consists in taking firm

hold of the planche, with

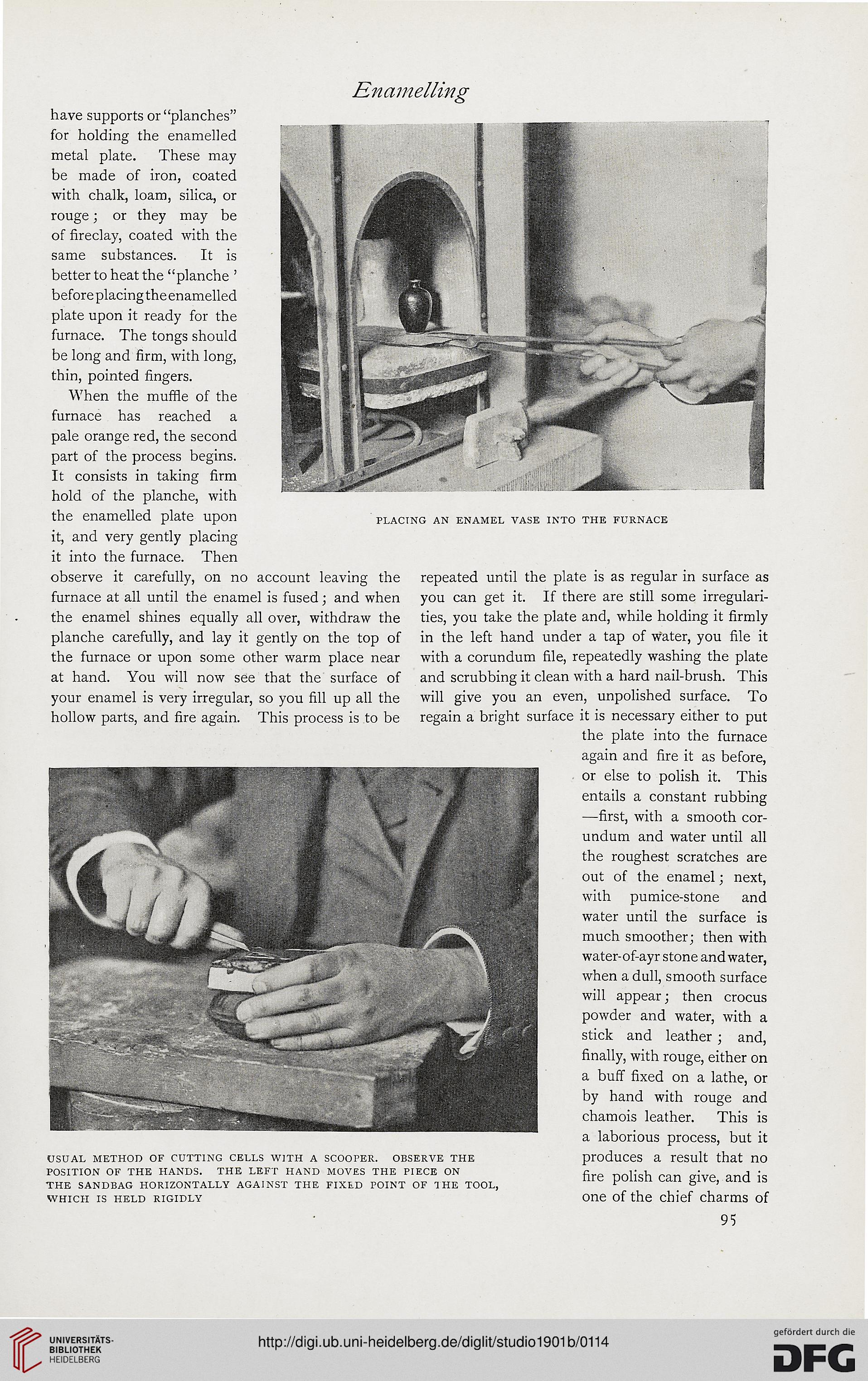

the enamelled plate upon placing an enamel vase into the furnace

it, and very gently placing

it into the furnace. Then

observe it carefully, on no account leaving the repeated until the plate is as regular in surface as

furnace at all until the enamel is fused; and when you can get it. If there are still some irregulari-

the enamel shines equally all over, withdraw the ties, you take the plate and, while holding it firmly

planche carefully, and lay it gently on the top of in the left hand under a tap of water, you file it

the furnace or upon some other warm place near with a corundum file, repeatedly washing the plate

at hand. You will now see that the surface of and scrubbing it clean with a hard nail-brush. This

your enamel is very irregular, so you fill up all the will give you an even, unpolished surface. To

hollow parts, and fire again. This process is to be regain a bright surface it is necessary either to put

the plate into the furnace

again and fire it as before,

or else to polish it. This

entails a constant rubbing

—first, with a smooth cor-

undum and water until all

the roughest scratches are

out of the enamel; next,

with pumice-stone and

water until the surface is

much smoother; then with

water-of-ayr stone and water,

when a dull, smooth surface

will appear; then crocus

powder and water, with a

stick and leather ; and,

finally, with rouge, either on

a buff fixed on a lathe, or

by hand with rouge and

chamois leather. This is

a laborious process, but it

usual method of cutting cells with a scooper. observe the produces a result that nO

position of the hands. the left iiand moves the piece on fire ^I^u „„ „J „ j j

the sandbag horizontally against the fixed point of the tool, " _ ° '

which is held rigidly one of the chief charms of

95

have supports or "planches"

for holding the enamelled

metal plate. These may

be made of iron, coated

with chalk, loam, silica, or

rouge; or they may be

of fireclay, coated with the

same substances. It is

better to heat the "planche '

before placing the enamelled

plate upon it ready for the

furnace. The tongs should

be long and firm, with long,

thin, pointed fingers.

When the muffle of the

furnace has reached a

pale orange red, the second

part of the process begins.

It consists in taking firm

hold of the planche, with

the enamelled plate upon placing an enamel vase into the furnace

it, and very gently placing

it into the furnace. Then

observe it carefully, on no account leaving the repeated until the plate is as regular in surface as

furnace at all until the enamel is fused; and when you can get it. If there are still some irregulari-

the enamel shines equally all over, withdraw the ties, you take the plate and, while holding it firmly

planche carefully, and lay it gently on the top of in the left hand under a tap of water, you file it

the furnace or upon some other warm place near with a corundum file, repeatedly washing the plate

at hand. You will now see that the surface of and scrubbing it clean with a hard nail-brush. This

your enamel is very irregular, so you fill up all the will give you an even, unpolished surface. To

hollow parts, and fire again. This process is to be regain a bright surface it is necessary either to put

the plate into the furnace

again and fire it as before,

or else to polish it. This

entails a constant rubbing

—first, with a smooth cor-

undum and water until all

the roughest scratches are

out of the enamel; next,

with pumice-stone and

water until the surface is

much smoother; then with

water-of-ayr stone and water,

when a dull, smooth surface

will appear; then crocus

powder and water, with a

stick and leather ; and,

finally, with rouge, either on

a buff fixed on a lathe, or

by hand with rouge and

chamois leather. This is

a laborious process, but it

usual method of cutting cells with a scooper. observe the produces a result that nO

position of the hands. the left iiand moves the piece on fire ^I^u „„ „J „ j j

the sandbag horizontally against the fixed point of the tool, " _ ° '

which is held rigidly one of the chief charms of

95