432

THE ILLUSTRATED EXHIBITOR.

the application of the common weaving-reed to the cir-

cular frame.

These machines are very extensively used in Notting-

ham. The numher of " feeders" now at work is upwards

of 6,000, each knitting from 4 lbs. to 6 lbs. of yarn a day.

Some of the machines are so constructed, that a girl, 15 or

16 years of age, is enabled with ease to work four feeders

at a time ; and the produce of her ordinary day's labour

from such a frame is material sufficient for 20 dozen pairs

of stockings In addition to this large number known t«

be employed, many others, which are adaptations of the

Chevalier Claussen's loom, are worked secretly in varied

parts of the town and neighbourhood of Nottingham T®

the extended employment of these machines in NotW

ham 1S mainly to be attributed the bringing-back to thai

town of the whole of the cheap stocking trade, which

up to a very recent period, was carried on in Saxonv TV

Council medal has been awaided to this Chevalier '

ELLIOTT'S WEIGHING MACHINE.

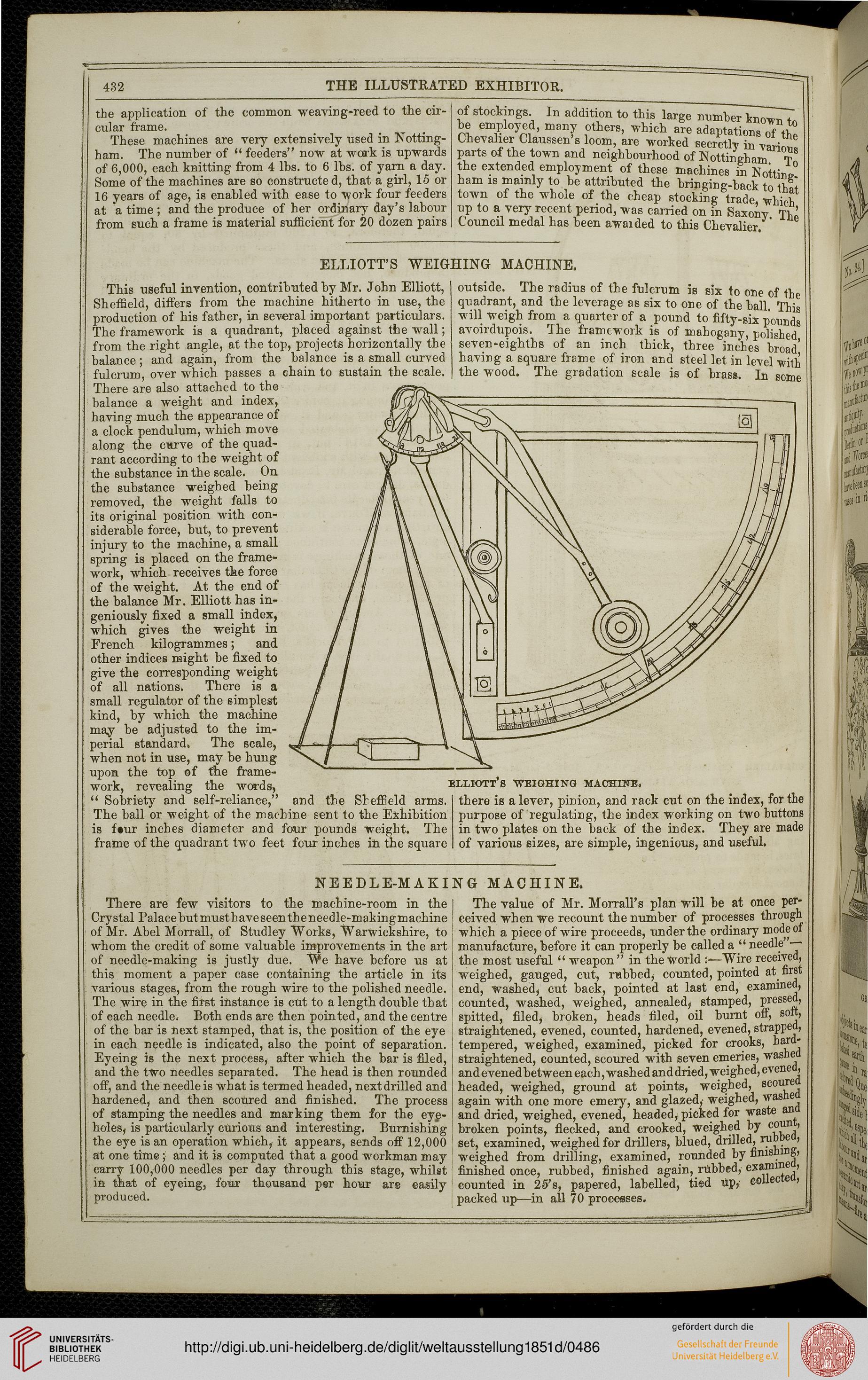

This useful invention, contributed by Mr. John Elliott,

Sheffield, differs from the machine hitherto in use, the

production of his father, in several important particulars.

The framework is a quadrant, placed against the wall;

from the right angle, at the top, projects horizontally the

balance; and again, from the balance is a small curved

fulcrum, oyer which passes a chain to sustain the scale.

There are also attached to the

balance a weight and index,

having much the appearance of

a clock pendulum, which move

along the curve of the quad-

rant according to the weight of

the substance in the scale. On

the substance weighed being

removed, the weight falls to

its original position with con-

siderable force, but, to prevent

injury to the machine, a small

spring is placed on the frame-

work, which receives the force

of the weight. At the end of

the balance Mr. Elliott has in-

geniously fixed a small index,

which gives the weight in

French kilogrammes; and

other indices might be fixed to

give the corresponding weight

of all nations. There is a

small regulator of the simplest

kind, by which the machine

may be adjusted to the im-

perial standard, The scale,

when not in use, may be hung

upon the top of the frame-

work, revealing the words,

" Sobriety and self-reliance,'* and the Sheffield arms.

The ball or weight of the machine sent to the Exhibition

is f«ur inches diameter and four pounds weight. The

frame of the quadrant two feet four inches in the square

outside. The radius of the fulcrum is six to one of the

quadrant, and the leverage as six to one of the ball. This

will weigh from a quarter of a pound to fifty-six pounds

avoirdupois. The framework is of mahogany, polished

seven-eighths of an inch thick, three inches broad'

having a square frame of iron and steel let in level with

the wood. The gradation scale is of brass. In some

Elliott's weighing machine,

there is a lever, pinion, and rack cut on the index, for the

purpose of regulating, the index Working on two buttons

in two plates on the back of the index. They are made

of various sizes, are simple, ingenious, and useful.

NEEDLE-MAKING MACHINE.

There are few visitors to the machine-room in the

Crystal Palacebutmusthaveseentheneedle-makingmachine

of Mr. Abel Morrall, of Studley "Works, "Warwickshire, to

whom the credit of some valuable improvements in the art

of needle-making is justly due. "We have before us at

this moment a paper case containing the article in its

various stages, from the rough wire to the polished needle.

The wire in the first instance is cut to a length double that

of each needle. Both ends are then pointed, and the centre

of the bar is next stamped, that is, the position of the eye

in each needle is indicated, also the point of separation.

Eyeing is the next process, after which the bar is filed,

and the two needles separated. The head is then rounded

off, and the needle is what is termed headed, next drilled and

hardened, and then scoured and finished. The process

of stamping the needles and marking them for the eye-

holes, is particularly curious and interesting. Burnishing

the eye is an operation which, it appears, sends off 12,000

at one time; and it is computed that a good workman may

carry 100,000 needles per day through this stage, whilst

in that of eyeing, four thousand per hour are easily

produced.

The value of Mr. Morrall's plan will be at once per-

ceived when we recount the number of processes through

which a piece of wire proceeds, under the ordinary modeoi

manufacture, before it can properly be called a " needle •—■

the most useful " weapon" in the world s—Wire received,

weighed, gauged, cut, rubbed* counted, pointed at first

end, washed* cut back, pointed at last end, examined,

counted, washed, weighed, annealed* stamped, pressed,

spitted, filed, broken, heads filed, oil burnt off, son,

straightened, evened, counted, hardened, evened, strapped,

tempered, weighed, examined, picked for crooks, Ba*"d"

straightened, counted, scoured with seven emeries, washed

and evened between each, washed anddried, weighed, evened,

headed, weighed, ground at points, weighed, scou5e^

again with one more emery, and glazed,- Weighed, washed

and dried, weighed, evened, headed* picked for waste and

broken points, flecked, and crooked, weighed by count,

set, examined, weighed for drillers, blued, drilled, ^bbea,

weighed from drilling, examined, rounded by finishing,

finished once, rubbed, finished again, nibbed, examinee,

counted in 25's, papered, labelled, tied up,-

collected,

packed up—in all 70 processes.

-■——~ -■•

----■'- *

THE ILLUSTRATED EXHIBITOR.

the application of the common weaving-reed to the cir-

cular frame.

These machines are very extensively used in Notting-

ham. The numher of " feeders" now at work is upwards

of 6,000, each knitting from 4 lbs. to 6 lbs. of yarn a day.

Some of the machines are so constructed, that a girl, 15 or

16 years of age, is enabled with ease to work four feeders

at a time ; and the produce of her ordinary day's labour

from such a frame is material sufficient for 20 dozen pairs

of stockings In addition to this large number known t«

be employed, many others, which are adaptations of the

Chevalier Claussen's loom, are worked secretly in varied

parts of the town and neighbourhood of Nottingham T®

the extended employment of these machines in NotW

ham 1S mainly to be attributed the bringing-back to thai

town of the whole of the cheap stocking trade, which

up to a very recent period, was carried on in Saxonv TV

Council medal has been awaided to this Chevalier '

ELLIOTT'S WEIGHING MACHINE.

This useful invention, contributed by Mr. John Elliott,

Sheffield, differs from the machine hitherto in use, the

production of his father, in several important particulars.

The framework is a quadrant, placed against the wall;

from the right angle, at the top, projects horizontally the

balance; and again, from the balance is a small curved

fulcrum, oyer which passes a chain to sustain the scale.

There are also attached to the

balance a weight and index,

having much the appearance of

a clock pendulum, which move

along the curve of the quad-

rant according to the weight of

the substance in the scale. On

the substance weighed being

removed, the weight falls to

its original position with con-

siderable force, but, to prevent

injury to the machine, a small

spring is placed on the frame-

work, which receives the force

of the weight. At the end of

the balance Mr. Elliott has in-

geniously fixed a small index,

which gives the weight in

French kilogrammes; and

other indices might be fixed to

give the corresponding weight

of all nations. There is a

small regulator of the simplest

kind, by which the machine

may be adjusted to the im-

perial standard, The scale,

when not in use, may be hung

upon the top of the frame-

work, revealing the words,

" Sobriety and self-reliance,'* and the Sheffield arms.

The ball or weight of the machine sent to the Exhibition

is f«ur inches diameter and four pounds weight. The

frame of the quadrant two feet four inches in the square

outside. The radius of the fulcrum is six to one of the

quadrant, and the leverage as six to one of the ball. This

will weigh from a quarter of a pound to fifty-six pounds

avoirdupois. The framework is of mahogany, polished

seven-eighths of an inch thick, three inches broad'

having a square frame of iron and steel let in level with

the wood. The gradation scale is of brass. In some

Elliott's weighing machine,

there is a lever, pinion, and rack cut on the index, for the

purpose of regulating, the index Working on two buttons

in two plates on the back of the index. They are made

of various sizes, are simple, ingenious, and useful.

NEEDLE-MAKING MACHINE.

There are few visitors to the machine-room in the

Crystal Palacebutmusthaveseentheneedle-makingmachine

of Mr. Abel Morrall, of Studley "Works, "Warwickshire, to

whom the credit of some valuable improvements in the art

of needle-making is justly due. "We have before us at

this moment a paper case containing the article in its

various stages, from the rough wire to the polished needle.

The wire in the first instance is cut to a length double that

of each needle. Both ends are then pointed, and the centre

of the bar is next stamped, that is, the position of the eye

in each needle is indicated, also the point of separation.

Eyeing is the next process, after which the bar is filed,

and the two needles separated. The head is then rounded

off, and the needle is what is termed headed, next drilled and

hardened, and then scoured and finished. The process

of stamping the needles and marking them for the eye-

holes, is particularly curious and interesting. Burnishing

the eye is an operation which, it appears, sends off 12,000

at one time; and it is computed that a good workman may

carry 100,000 needles per day through this stage, whilst

in that of eyeing, four thousand per hour are easily

produced.

The value of Mr. Morrall's plan will be at once per-

ceived when we recount the number of processes through

which a piece of wire proceeds, under the ordinary modeoi

manufacture, before it can properly be called a " needle •—■

the most useful " weapon" in the world s—Wire received,

weighed, gauged, cut, rubbed* counted, pointed at first

end, washed* cut back, pointed at last end, examined,

counted, washed, weighed, annealed* stamped, pressed,

spitted, filed, broken, heads filed, oil burnt off, son,

straightened, evened, counted, hardened, evened, strapped,

tempered, weighed, examined, picked for crooks, Ba*"d"

straightened, counted, scoured with seven emeries, washed

and evened between each, washed anddried, weighed, evened,

headed, weighed, ground at points, weighed, scou5e^

again with one more emery, and glazed,- Weighed, washed

and dried, weighed, evened, headed* picked for waste and

broken points, flecked, and crooked, weighed by count,

set, examined, weighed for drillers, blued, drilled, ^bbea,

weighed from drilling, examined, rounded by finishing,

finished once, rubbed, finished again, nibbed, examinee,

counted in 25's, papered, labelled, tied up,-

collected,

packed up—in all 70 processes.

-■——~ -■•

----■'- *