COLOUR-PRINTING FROM WOOD-BLOCKS

within the angle of the right-angled nick

should be removed with a flat chisel to

the depth of, say, the thickness of a post

card. The left-hand nick should be treated

similarly. 00000

Indian ink should have been prepared

beforehand for printing with. A stick of

good ink should be broken up and placed

in a cup of water and left for two or three

days. The water, which has dissolved out

the gum or cementing material, is then

poured away, and the softened pieces

placed within a wide-mouthed bottle. To

prevent the contents emitting a putrid

odour, a drop of creasote may be poured on

a wad of paper fastened to the bottom of

the cork. 00000

The preparation of the colour-blocks

can now be commenced. Two or more

colour-blocks should be in readiness with

both sides well pasted, as well as the

second surface of the key-block, but before

this the paper left on the lines of the key-

block should be gently washed off with a

brush or soft sponge. The block should

be partly dried, and loose bits of damp

paper removed. Generally it will be found

that more clearing away of waste spaces

remains to be done. 000

Some of the softened ink should now be

taken out of the bottle with a palette-knife,

an ivory one for preference, and rubbed

down on a plate or slab, with a drop of water

if not moist enough. The black should be

applied to the block with a broad brush. A

Japanese brush is here shown, but a varnish-

brush, or even a stencil-brush, will prove

efficient. The brush should be used vigor-

ously at first to ensure even distribution, but

the last strokes should merely caress the

block. Some pieces of Japanese tracing-

paper, rather larger than the print, should be

in readiness. One of these should be laid

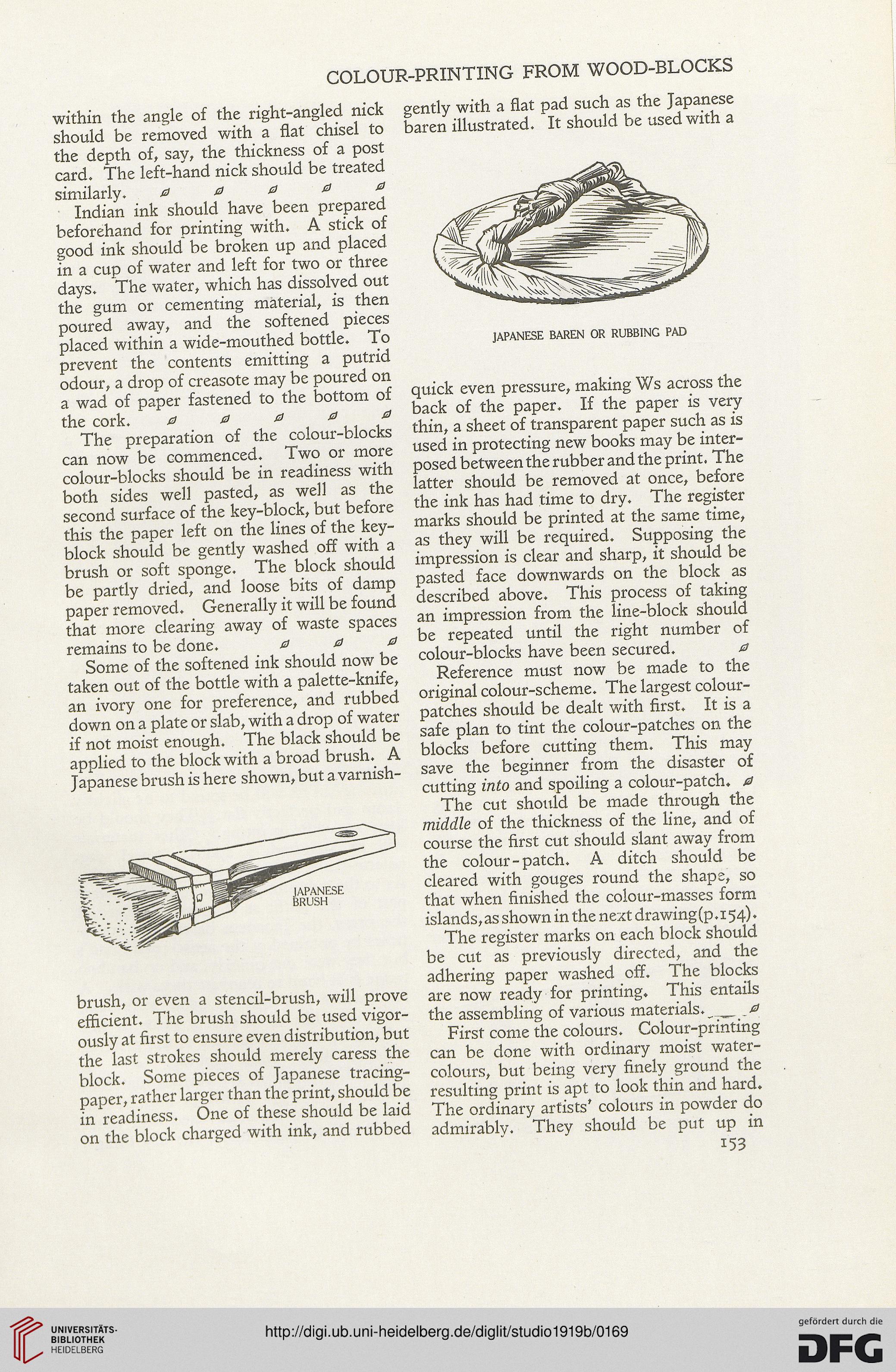

on the block charged with ink, and rubbed

gently with a flat pad such as the Japanese

baren illustrated. It should be used with a

JAPANESE BAREN OR RUBBING PAD

quick even pressure, making Ws across the

back of the paper. If the paper is very

thin, a sheet of transparent paper such as is

used in protecting new books may be inter-

posed between the rubber and the print. The

latter should be removed at once, before

the ink has had time to dry. The register

marks should be printed at the same time,

as they will be required. Supposing the

impression is clear and sharp, it should be

pasted face downwards on the block as

described above. This process of taking

an impression from the line-block should

be repeated until the right number of

colour-blocks have been secured. 0

Reference must now be made to the

original colour-scheme. The largest colour-

patches should be dealt with first. It is a

safe plan to tint the colour-patches on the

blocks before cutting them. This may

save the beginner from the disaster of

cutting into and spoiling a colour-patch. 0

The cut should be made through the

middle of the thickness of the line, and of

course the first cut should slant away from

the colour-patch. A ditch should be

cleared with gouges round the shape, so

that when finished the colour-masses form

islands, as shown in the next drawing(p. 154).

The register marks on each block should

be cut as previously directed, and the

adhering paper washed off. The blocks

are now ready for printing. This entails

the assembling of various materials._0

First come the colours. Colour-printing

can be done with ordinary moist water-

colours, but being very finely ground the

resulting print is apt to look thin and hard.

The ordinary artists' colours in powder do

admirably. They should be put up in

153

within the angle of the right-angled nick

should be removed with a flat chisel to

the depth of, say, the thickness of a post

card. The left-hand nick should be treated

similarly. 00000

Indian ink should have been prepared

beforehand for printing with. A stick of

good ink should be broken up and placed

in a cup of water and left for two or three

days. The water, which has dissolved out

the gum or cementing material, is then

poured away, and the softened pieces

placed within a wide-mouthed bottle. To

prevent the contents emitting a putrid

odour, a drop of creasote may be poured on

a wad of paper fastened to the bottom of

the cork. 00000

The preparation of the colour-blocks

can now be commenced. Two or more

colour-blocks should be in readiness with

both sides well pasted, as well as the

second surface of the key-block, but before

this the paper left on the lines of the key-

block should be gently washed off with a

brush or soft sponge. The block should

be partly dried, and loose bits of damp

paper removed. Generally it will be found

that more clearing away of waste spaces

remains to be done. 000

Some of the softened ink should now be

taken out of the bottle with a palette-knife,

an ivory one for preference, and rubbed

down on a plate or slab, with a drop of water

if not moist enough. The black should be

applied to the block with a broad brush. A

Japanese brush is here shown, but a varnish-

brush, or even a stencil-brush, will prove

efficient. The brush should be used vigor-

ously at first to ensure even distribution, but

the last strokes should merely caress the

block. Some pieces of Japanese tracing-

paper, rather larger than the print, should be

in readiness. One of these should be laid

on the block charged with ink, and rubbed

gently with a flat pad such as the Japanese

baren illustrated. It should be used with a

JAPANESE BAREN OR RUBBING PAD

quick even pressure, making Ws across the

back of the paper. If the paper is very

thin, a sheet of transparent paper such as is

used in protecting new books may be inter-

posed between the rubber and the print. The

latter should be removed at once, before

the ink has had time to dry. The register

marks should be printed at the same time,

as they will be required. Supposing the

impression is clear and sharp, it should be

pasted face downwards on the block as

described above. This process of taking

an impression from the line-block should

be repeated until the right number of

colour-blocks have been secured. 0

Reference must now be made to the

original colour-scheme. The largest colour-

patches should be dealt with first. It is a

safe plan to tint the colour-patches on the

blocks before cutting them. This may

save the beginner from the disaster of

cutting into and spoiling a colour-patch. 0

The cut should be made through the

middle of the thickness of the line, and of

course the first cut should slant away from

the colour-patch. A ditch should be

cleared with gouges round the shape, so

that when finished the colour-masses form

islands, as shown in the next drawing(p. 154).

The register marks on each block should

be cut as previously directed, and the

adhering paper washed off. The blocks

are now ready for printing. This entails

the assembling of various materials._0

First come the colours. Colour-printing

can be done with ordinary moist water-

colours, but being very finely ground the

resulting print is apt to look thin and hard.

The ordinary artists' colours in powder do

admirably. They should be put up in

153