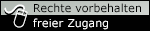

FIG I.—MODELLIKG FIGURES

dashed on the face of the model, covering the

whole surface to the depth of about one-fourth of

face (or the part wished to be cast) up-

wards. The operator now washes out

the mould with a very soft brush, so

that it may not be injured, the opera-

tion being repeated tiil the mouid is

perfectly ciean. The whoie mouid is

next washed, soaped and oiied, white

wood rules are now tacked round the

edge of the cast to the necessary thick-

ness, and scrim and iaths cut to the

proper sizes.

It now remains oniy to fiil in the

plaster. First a coat is laid on ail over

and aiiowed to partialiy set, then the

scrim and laths are carefuliy piaced and

more piaster brushed on, more scrim

being also added if necessary. After

the plaster has set the whoie is turned

upon edge, with the back of the mouid

outwards, which is now chipped off

from the cast with maliet and chisei

(as in Fig. 4). When the operator

comes on the coioured casting, he of course recog-

nises that he is very near the face of the cast, and

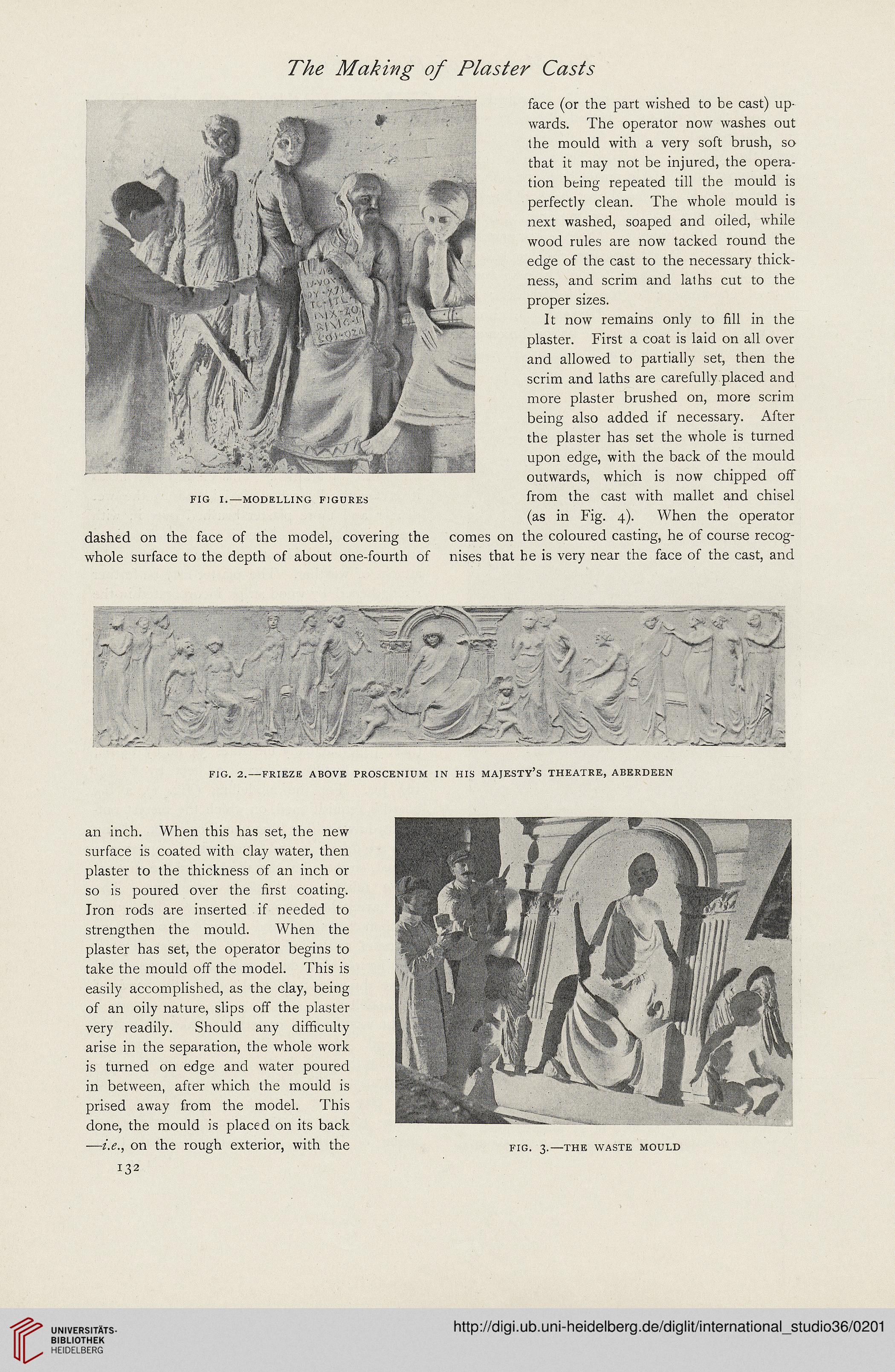

an inch. When this has set, the new

surface is coated with ciay water, then

piaster to the thickness of an inch or

so is poured over the first coating.

Iron rods are inserted if needed to

strengthen the mould. When the

piaster has set, the operator begins to

take the mould off the modei. This is

easiiy accompiished, as the ciay, being

of an oiiy nature, siips oif the plaster

very readiiy. Shouid any difficuity

arise in the separation, the whole work

is turned on edge and water poured

in between, after which the mould is

prised away from the model. This

done, the mould is placed on its back

—f.^., on the rough exterior, with the

132

FIG. 3.—THE WASTE M0ULD